Page 29

IN ADDITION TO THE SIX BASIC STEPS OF OPERATION, THE OPERATOR SHOULD ALSO

BE FAMILIAR WITH THE FOLLOWING:

A.

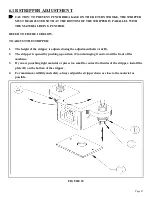

MAINTAIN PROPER BLADE CLEARANCE.

The quality of the cut is an immediate indication of the condition of the Shear Blades, the amount of

clearance between the blades or the amount of "spring-back" in the Shear Arm.

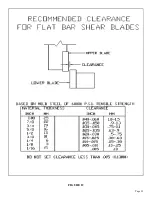

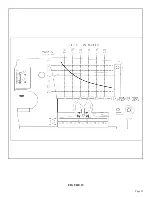

The Shear Blades are symmetrical and can be rotated to expose four (4) cutting edges. For recommended

clearances, SEE FIGURE 12 ON PAGE 33.

B.

ALL CUTS SHOULD BE MADE AS FAR FROM THE ARM PIVOT AS POWER WILL PERMIT.

The Shear Blades should contact the workpiece as flat as possible, to reduce to a minimum the amount of

"curl" on the cut-off piece. More shearing force is obtained as the operator moves the workpiece toward

the left. The machine is designed to shear mild steel rated on 60,000 tensile.

The maximum capacity of the bar shear is 1 x 6 inch (25 x 150mm) mild steel.

Summary of Contents for IRONWORKER 6509-24M

Page 1: ...Page 1 MODEL 6509 24M IRONWORKER PRINTED MARCH 2005...

Page 9: ...Page 9 FIGURE 1...

Page 17: ...Page 17 FIGURE 5...

Page 19: ...Page 19 FIGURE 6...

Page 21: ...Page 21 FIGURE 7...

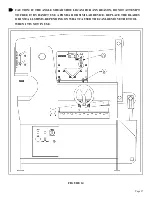

Page 31: ...Page 31 FIGURE 11...

Page 33: ...Page 33 FIGURE 12...

Page 35: ...Page 35 FIGURE 13...

Page 39: ...Page 39 FIGURE 15...

Page 41: ...Page 41 FIGURE 16...

Page 47: ...Page 47 FIGURE 20...

Page 51: ...Page 51 FIGURE 22...

Page 55: ...Page 55 FIGURE 25...

Page 59: ...Page 59 FIGURE 27...

Page 69: ...Page 69 FIGURE 30...

Page 71: ...Page 71 FIGURE 31...

Page 75: ...Page 75 FIGURE 34...

Page 79: ...Page 79 FIGURE 37...

Page 81: ...Page 81 FIGURE 38...

Page 85: ...Page 85 FIGURE 40 Serial s 5035FF1094 to 7124FF103...