Page 45

7.5B BRAKE OPERATION

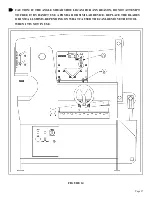

NEVER PUT YOUR HANDS INTO OR AROUND A BRAKE WHILE IT IS IN OPERATION.

Grease the slider block between the upper arm and the tool every two hours of operation.

Hold short pieces with tongs or a similar device. In using the brake, it is necessary to load the brake

centrally. (Visual centering is sufficient.) If work is performed off-center, the guide pins could be

damaged. The brake lift is provided by springs. If sticking occurs at the bottom of the stroke and the

upper die does not return, usually a slight tap on the upper die is sufficient to free the guides.

DO NOT ATTEMPT TO FREE THE BRAKE BY HAND.

Sticking can be caused by lack of lubrication, complexity of the part being bent or bent guide pins. Keep

the guides well lubricated and replace them if they are damaged.

It is common practice to have the bottom die opening 8 times the thickness of the material being bent. If

the parts require a bend of less than 90 degrees, adjust the down-stroke of the machine until the desired

bend is obtained. A great variety of standard brake dies can be used with this unit. These are available

from Scotchman Industries or Brake Die suppliers.

REMOVE THE TOOL WHEN IT IS NOT IN USE.

FIGURE 19

Summary of Contents for IRONWORKER 6509-24M

Page 1: ...Page 1 MODEL 6509 24M IRONWORKER PRINTED MARCH 2005...

Page 9: ...Page 9 FIGURE 1...

Page 17: ...Page 17 FIGURE 5...

Page 19: ...Page 19 FIGURE 6...

Page 21: ...Page 21 FIGURE 7...

Page 31: ...Page 31 FIGURE 11...

Page 33: ...Page 33 FIGURE 12...

Page 35: ...Page 35 FIGURE 13...

Page 39: ...Page 39 FIGURE 15...

Page 41: ...Page 41 FIGURE 16...

Page 47: ...Page 47 FIGURE 20...

Page 51: ...Page 51 FIGURE 22...

Page 55: ...Page 55 FIGURE 25...

Page 59: ...Page 59 FIGURE 27...

Page 69: ...Page 69 FIGURE 30...

Page 71: ...Page 71 FIGURE 31...

Page 75: ...Page 75 FIGURE 34...

Page 79: ...Page 79 FIGURE 37...

Page 81: ...Page 81 FIGURE 38...

Page 85: ...Page 85 FIGURE 40 Serial s 5035FF1094 to 7124FF103...