Page 63

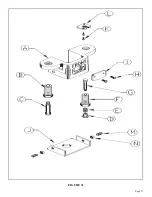

8.4 HYDRAULICS

THE MOST COMMON HYDRAULIC PROBLEMS ARE:

1.

Low level of hydraulic oil in the reservoir: The reservoir holds 12 U.S. gallons (45 Liters). The level

should be 1" below the top of the reservoir.

2.

Contamination in the hydraulic oil: The oil and the filter should be changed at least once a year and

any time there is a possibility that contamination has gained access into the system.

For recommended hydraulic oil, SEE SECTION 5.2.

3.

Low pressure caused by worn or damaged parts in the cylinder or pump: There is a pressure port

for a pressure gauge provided on all machines. The port will be on the valve manifold or the

pressure line between the pump and the valve. A gauge with a minimum capacity of 3,000 PSI is

required. With the machine’s power off, install the pressure gauge. Power the machine and place a

piece of steel in the shear section and clamp it down with the hold down device. Attempt to shear the

piece, watching the pressure gauge for a reading. The system pressure of this machine is 2,700 PSI.

The pressure is adjustable by adjusting in the relief valve adjustment on the control valve manifold.

If the pressure cannot be increased, call your local dealer or the factory.

Summary of Contents for IRONWORKER 6509-24M

Page 1: ...Page 1 MODEL 6509 24M IRONWORKER PRINTED MARCH 2005...

Page 9: ...Page 9 FIGURE 1...

Page 17: ...Page 17 FIGURE 5...

Page 19: ...Page 19 FIGURE 6...

Page 21: ...Page 21 FIGURE 7...

Page 31: ...Page 31 FIGURE 11...

Page 33: ...Page 33 FIGURE 12...

Page 35: ...Page 35 FIGURE 13...

Page 39: ...Page 39 FIGURE 15...

Page 41: ...Page 41 FIGURE 16...

Page 47: ...Page 47 FIGURE 20...

Page 51: ...Page 51 FIGURE 22...

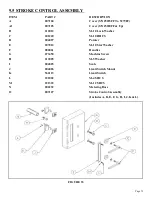

Page 55: ...Page 55 FIGURE 25...

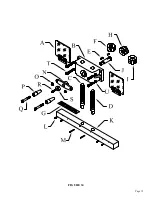

Page 59: ...Page 59 FIGURE 27...

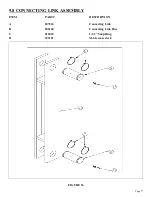

Page 69: ...Page 69 FIGURE 30...

Page 71: ...Page 71 FIGURE 31...

Page 75: ...Page 75 FIGURE 34...

Page 79: ...Page 79 FIGURE 37...

Page 81: ...Page 81 FIGURE 38...

Page 85: ...Page 85 FIGURE 40 Serial s 5035FF1094 to 7124FF103...