•

The machine must be connected to 220V 3ph or 440V 3ph power.

•

To ensure satisfactory machine performance, the supply voltage should (+ or -) 10% of the motor

voltage rating. Check the machine data tag for full load current requirements.

•

For electrical supply lines ten feet (3m) or shorter, we recommend at least 12 gauge, and

preferably, 10. For longer electrical supply lines, use at least 10 gauge, and preferably, 8.

•

We do not recommend supply lines longer than twenty five feet (7.5m).

•

The electric circuit must be protected by a fuse or circuit breaker with an adequate rating.

•

The motor direction can be changed by swapping (2) of the incoming phases - See SECT. 3.11.

•

The motor must be running in correct direction before the system can be de-aerated (SECT. 5.1)

3.10 ELECTRICAL REQUIREMENTS

CAUTION:

TO PREVENT DAMAGE TO THE MOTOR AND DANGER TO THE

OPERATOR, ALL ELECTRICAL CONNECTIONS SHOULD BE MADE

BY A LICENSED ELECTRICIAN.

Page 18

►

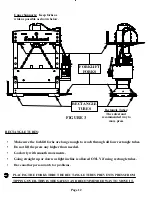

NOTE: CHECK WHICH DIRECTION THE MOTOR IS TURNING. LOOKING AT THE

MOTOR FROM ABOVE, MAKE SURE THE MOTOR IS TURNING THE

DIRECTION INDICATED BY THE ARROW.

CAUTION: IF THE MOTOR IS RUNNING IN THE WRONG DIRECTION, IT CAN

DAMAGE THE MACHINE IN A VERY SHORT TIME!!