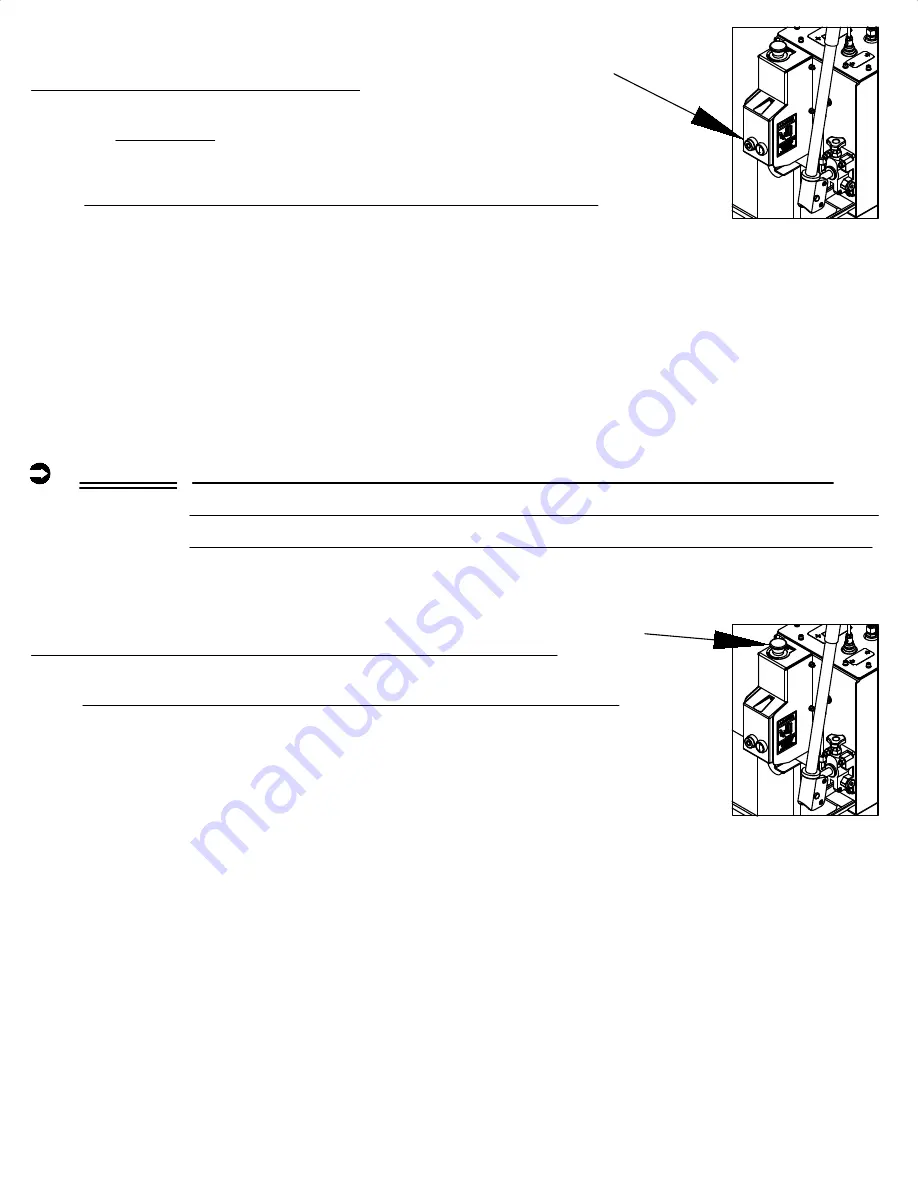

4.1 ON/OFF SWITCH

Refer to FIGURE 10 for the following:

1. The on / off switch is situated at the front of the hydraulic tank

•

Pushing the green button will start the motor of the hydraulic unit. There will be no movement of

any part after the motor starts running.

•

Pushing the red button will stop the motor on the hydraulic unit immediately. All parts will stay in

the position they are at that moment.

WARNING: NEVER TURN OFF THE MACHINE WHEN PRESSING FORCE IS BEING

APPLIED TO THE WORK PIECE. UNEXPECTED FORCE EXPANSION WHEN

RESTARTING CAN DAMAGE THE MACHINE OR INJURE THE OPERATOR.

4.2 EMERGENCY STOP BUTTON

2. The emergency stop button is located on top of the on / off switch.

•

Pushing the red emergency stop button in case of emergency will

stop the

electric motor on the

hydraulic unit immediately.

•

All other

parts will stay in the same position they are at that moment.

To restart the hydraulic unit after using emergency stop:

•

Make sure that the dangerous situation has been resolved.

•

Reset the red emergency stop button by turning it clockwise, the button will pop-up again.

•

Push the green button from the on / off switch again.

Page 22