► NOTE: REPLACING PARTS, ELECTRICAL, MECHANICAL OR HYDRAULIC, MUST BE

DONE BY QUALIFIED PERSONNEL. SCOTCHMAN IND. CAN NOT BE HELD

RESPONSIBLE FOR DAMAGES OR INJURIES CAUSED BY IMPROPER SERVICING.

► NOTE: WHEN PERFORMING MAINTENANCE, ALWAYS FOLLOW OSHA LOCKOUT-

TAGOUT PROCEDURES. MAKE SURE POWER IS OFF AND THERE IS NO

HYDRAULIC PRESSURE IN THE SYSTEM. BOTH CAN RESULT IN INJURIES TO

THE MAINTENANCE OPERATOR.

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844 www.scotchman.com

Page 31

7.0 PRESSPRO 110 MAINTENANCE

A program of scheduled maintenance should be set up and documented according to your application

and the frequency you use this machine. The following is a list of important items that should be

included in a scheduled maintenance program:

1. DAILY

•

Make sure press and area around press is clean and uncluttered.

•

Inspect press for any visible damage or wear.

2. EVERY WEEK

•

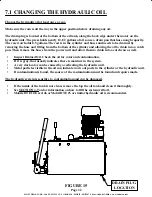

Check the hydraulic oil level via the sight glass on the rear of the hydraulic unit.

•

Inspect electrical connections including power cord.

•

Inspect lifting chains including the lifting yoke.

3. EVERY SIX MONTHS

•

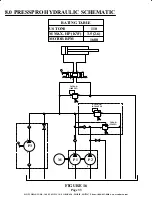

Inspect all hydraulic fittings and hoses for signs of wear or leaks and tighten any loose connections.

•

Inspect all the bolts on the press and make sure all are tight.

4. EVERY YEAR

•

Change the hydraulic oil.

If any leaks, loose or damaged parts or bare electric cables are found; STOP USING THE PRESS.

Resume using press ONLY AFTER IT HAS BEEN REPAIRED.