PAGE 10

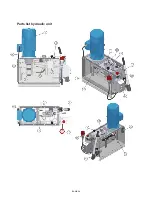

3.6 Oil tank filling

The press is delivered without oil. Before starting up, the tank needs to be filled.

Mobile DTE 10 Excel 46 or Mobile DTE 25 or similar hydraulic oil is recommended.

Bring the piston into its upper position.

Remove the filler plug on top of the hydraulic unit.

Replace the filler plug.

Start the hydraulic unit.

De-aerate the press: Lower the piston (with the direction control valve / joystick) 4 in. and

bring the piston back to its upper position. Then lower the piston 8 in. and bring it back

to the upper position. Then lower the piston 12 in. and then back to the upper position.

Then move the piston down again to 15 to 15-3/4 in. and bring it back up to the upper

position.

Turn off the hydraulic unit.

Remove the filler plug again and check oil level.

If needed, add more hydraulic oil to the tank.

Replace the filler plug.

To properly fill the oil tank:

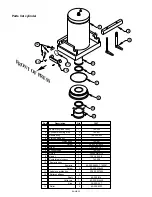

On top of the cylinder there are (2) threaded holes. The centered hole is for the large

diameter (18mm) hose from the reservoir. The other hole is for the small diameter

(5mm) pressure gauge hose.

Top of cylinder

Fig. 6 Keep hoses straight - no sharp bends

MAKE SURE ALL HOSES ARE TIGHTENED SECURELY AND CONNECTED IN THE

CORRECT LOCATION BEFORE FILLING RESERVOIR AND OPERATING THE PRESS

Make sure there are no sharp bends in the hoses between the clamps and connections

to the hydraulic unit as shown above.

Fill the tank with a sufficient amount of oil. The total capacity of this press including

the reservoir and cylinder is 15 gal. (57 liters).

Summary of Contents for PRESSPRO 176MT

Page 20: ...PAGE 20...