PAGE 14

5. Getting started

5.1 De-aerating the press

5.2 De-aerating the hand pump

5.3 Positioning of cylinder

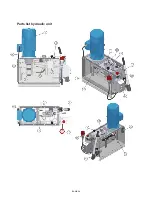

To start the press for the first time, make sure:

The press is installed correctly (see former paragraphs).

The oil tank is filled with a sufficient amount of oil.

The hydraulic hoses are tightened correctly to the cylinder and to the hydraulic unit.

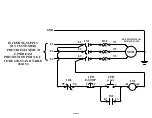

The machine is connected to the correct voltage & grounded per local code.

When starting up for the first time or when the hydraulic hoses have been disconnected from the

hydraulic unit or cylinder, the system need to be de-aerated. To do this:

Start with the piston in the upper position (as delivered condition).

Make sure there is no work piece on the table.

Start the hydraulic unit.

Move the piston to the down position by activating the directional control valve.

Move the piston back to the up position by activating the direction control valve.

Repeat this complete cycle at least 6 times to ensure that all the air is out of the system.

Note: incorrect de-aerating can cause unexpected movements of the piston and

cause the press to malfunction.

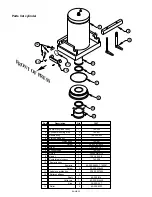

When starting up for the first time or when maintenance of the hydraulic unit is performed, the hand

pump needs to be de-aerated. To do this:

Start with the piston in the upper position.

Make sure there is no work piece on the table.

Turn off the hydraulic unit by pushing the red button at the on / off switch.

Set the directional control valve in the downwards position.

Start pumping the hand pump with its lever until the piston reaches the lower position.

Set the directional control valve in the upwards position.

Start pumping the hand pump with its lever until the piston reaches the upper position.

Repeat this complete cycle at least 3 times to be sure all air is out of the hand pump.

Note: incorrect de-aerating can cause unexpected movements of the piston and

cause the press to malfunction.

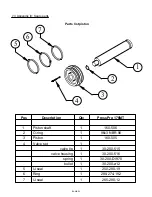

Move the complete cylinder to the left or right by means of the bow grip (handle).

Tighten the levers again when the cylinder is in the right position. Manual tightening is enough.

Do not use a wrench - Do not over-tighten the levers.

When your work with the press is finished, move the cylinder back in its center position.

Turn both levers two turns counter clockwise to loosen.

DO NOT COMPLETELY REMOVE THE LEVERS!!

All presses are equipped with a movable cylinder which makes it possible to correctly align

the press ram with the work piece. To move the cylinder side to side:

Summary of Contents for PRESSPRO 176MT

Page 20: ...PAGE 20...