PAGE 17

6

.

Servicing and maintenance

Note: replacing parts, electrical, mechanical or hydraulic, can only be done by

qualified personnel. Your supplier can not be held responsible for damages or

injuries as result of inappropriate servicing.

Daily

Remove dust and dirt

from the table and

around the press.

Check the press for

visible damages.

Weekly

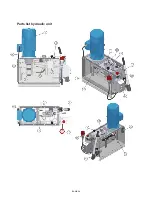

Check oil level of the

hydraulic unit.

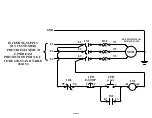

Check electrical

connections.

Half-yearly

Inspect all hydraulic

fittings and hoses and

tighten any loose

connections.

Inspect and tighten all

loose fixing bolts.

In case of leakages, damaged parts or bare electric cables; do not use the machine before it is

repaired.

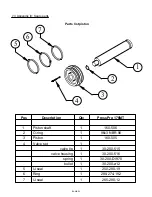

Always use original spare parts.

Note: when starting with maintenance, always unplug the electrical connection

and make sure there is no hydraulic pressure on the system. Both can result in

injuries to the maintenance operator.

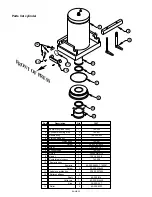

6.1 Oil tank draining

Replace the hydraulic oil at least once a year. A drain plug is located at the bottom of the oil tank. If

the inside of the tank is not clean, remove the top cover of the tank and clean the tank from the inside.

Check if the drained oil has a gray color or if there are metal particles visible in the oil. This can

indicate worn out parts in the cylinder or the hydraulic unit.

You have to prevent spilling dirt and water inside the oil tank.

6.2 Contact your supplier

If there are any questions, please contact your supplier.

Always mention the serial number on the machine label. This label is located at the frame of the press

(front right side). When you have questions about the hydraulic unit, also mention its serial number.

The label is located on the back of the hydraulic tank.

Yearly

Replace the hydraulic

oil of the unit. See

instruction below.

Fig. 16 Examples of type labels

SCOTCHMAN IND.

HYDRAULIC PRESS

MODEL

PRESSPRO 176MT

S/N 10061N120001

FRAME

HYDRAULIC TANK

Summary of Contents for PRESSPRO 176MT

Page 20: ...PAGE 20...