8.0 RECOMMENDATIONS & MAINTENANCE

8.1 TYPE & FREQUENCY OF REVIEWS

LUBRICATION POINTS

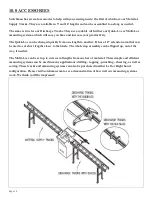

Arc turning bolt Fig. 11.2

Long belt-guide bracket Fig. 11.4

Bearings Fig. 11.4

CHECK

Saw blade tension

Level of coolant liquid

Cleanliness of machine

Cleanliness of coolant tank

Condition of nylon shaving guard

Fig 10.4

Saw blade guides

TYPE OF GREASE/OIL

Bearing grease

SAE 30

Bearing grease

MATERIALS TO USE

90-100 BAR (see gauge)

Top up with WHITE COOLANT

Diluted mild degreasing fluid

Damp cloth, brush

Replace, if necessary

Sections 7.1 & 7.2

FREQUENCY

Yearly

Weekly

Weekly

FREQUENCY

Daily

Daily

Weekly

Monthly

Monthly

Monthly

9.0 GENERAL RULES & SAFETY CHECKS

Before using the machine, check the effectiveness and perfect operation of the safety devices. Check

that the moving parts of the machine are not blocked, that there are no damaged parts and that all

of the machine components are positioned correctly and that they work properly.

Verify that the motor-guard switch works correctly by testing it during a no-load cycle of the

machine.

It is absolutely prohibited to altar any safety device.

It is absolutely prohibited to work without the guards in place.

It is mandatory to use gloves when changing the saw blade.

It is mandatory to use officially approved work clothing, which must be fastened.

Before starting work, the operator must be sure to remove all tools and wrenches that have been

used for any maintenance or adjustments.

In the event of fire, use powder extinguishers and disconnect the machine from the electric system.

Page 12

Summary of Contents for SU-280-G

Page 1: ...Page 1 MODEL SU 280 G BAND SAW...

Page 5: ...3 2 SELECTION OF THE BAND SAW Page 5...

Page 17: ...Page 17...

Page 19: ...Page 19...

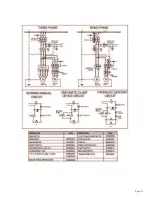

Page 20: ...Page 20 11 0 DRAWINGS SCHEMATICS 11 1 ELECTRICAL SCHEMATIC...

Page 21: ...Page 21...

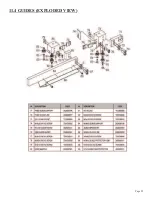

Page 22: ...Page 22 11 2 MACHINE EXPLODED VIEW...

Page 23: ...Page 23...