Page 13

9.1 MANUFACTURER'S RECOMMENDATIONS

Repairs shall be made exclusively by qualified personnel; using original replacement parts. If not,

the machine may be damaged and the user may be injured.

Maintenance and cleaning of the machine must be performed regularly. The life of the machine and

its optimal operation depend on it.

If the machine is broken down or the saw blade must be replaced, a lock must be placed on the

protection switch and the keys must be placed under the care of qualified personnel.

Before taking any repairs on electrical devices, disconnect the plug from the power supply.

In the event that extension cords are used, ensure that the cable used has the appropriate gauge

for the machine's power.

Whenever any part has to be replaced, use an original replacement part and endeavor to use the

oil recommended by the manufacturer.

NOTE: In case of any doubt or problem, do not hesitate to consult the manufacturer.

ATTENTION: The manufacturer hereby guarantees the supply of each one of the parts or

components for at least three years from the manufacturing date of the machine.

Summary of Contents for SU-280-G

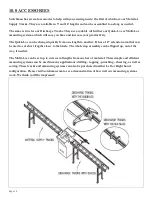

Page 1: ...Page 1 MODEL SU 280 G BAND SAW...

Page 5: ...3 2 SELECTION OF THE BAND SAW Page 5...

Page 17: ...Page 17...

Page 19: ...Page 19...

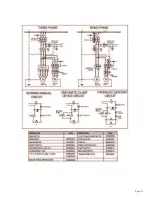

Page 20: ...Page 20 11 0 DRAWINGS SCHEMATICS 11 1 ELECTRICAL SCHEMATIC...

Page 21: ...Page 21...

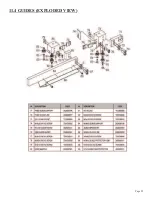

Page 22: ...Page 22 11 2 MACHINE EXPLODED VIEW...

Page 23: ...Page 23...