Page 8

5.4 CUTTING COOLANT

When filling the cutting coolant, use pure, synthetic water-soluble coolant and pour it in through the

coolant down-tube on the machine mount.

CAUTION: When it is necessary to empty the liquid coolant tank, do not improperly dispose of the

coolant.

ATTENTION: The use of any other kinds of coolants may cause irreparable damage to the machine,

as well as diminish the quality of the cut and reduce the life of the saw.

6.0 INSTRUCTIONS FOR USE

6.1 PROPER AND IMPROPER USE

Band saw machine for cutting all kinds of ferrous materials. Use of the machine for cutting other

materials is prohibited. Such use may cause damage to the machine and risk the safety of the worker.

DANGER: We are hereby not liable for any possible accident caused by the failure to comply with

the aforementioned provision.

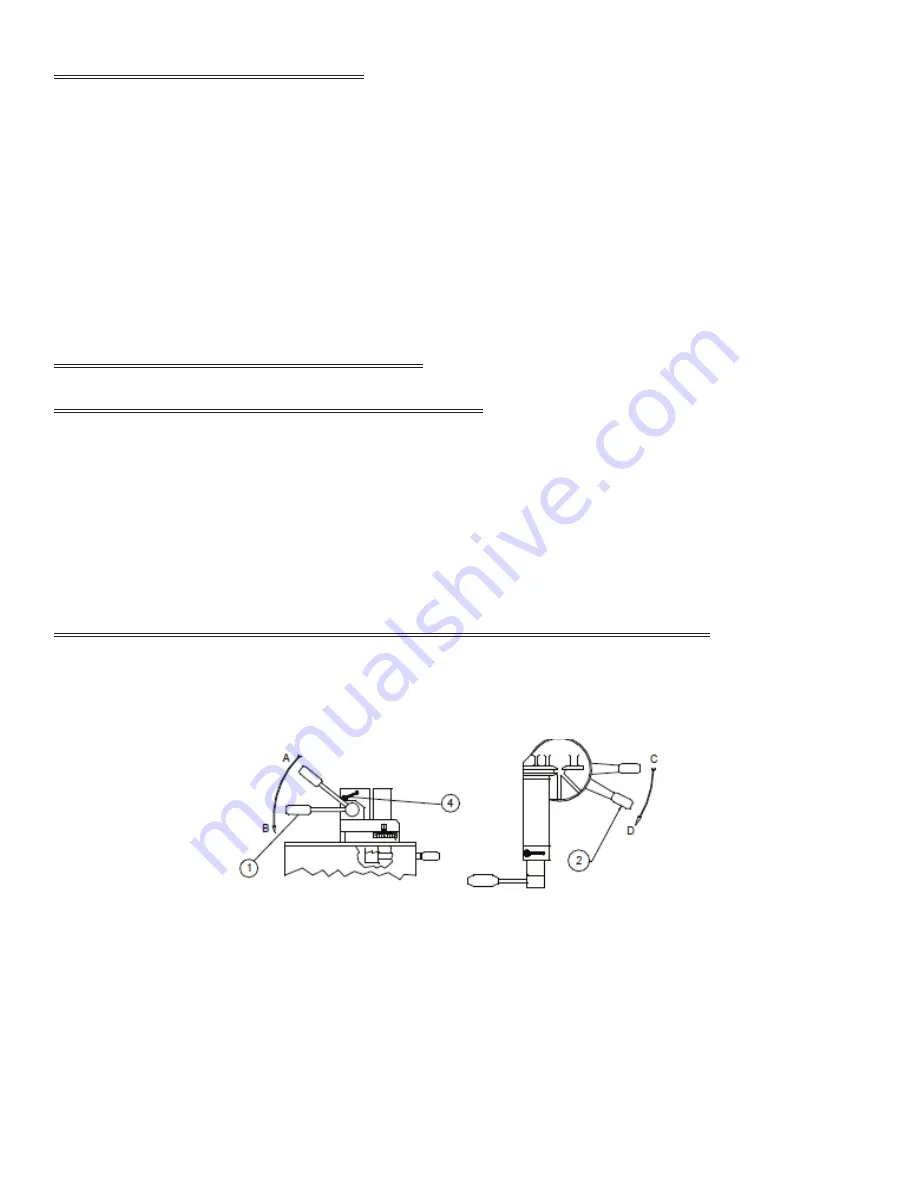

6.2 FUNCTION OF THE OPERATING MECHANISMS

1.

The vise is closed using lever no. 1. Work with the vise jaws less than ¼ inch (6 mm) from the

material to be secured.

2.

Angle locking lever. Set to position C to allow angled rotation.

Summary of Contents for SU-280-G

Page 1: ...Page 1 MODEL SU 280 G BAND SAW...

Page 5: ...3 2 SELECTION OF THE BAND SAW Page 5...

Page 17: ...Page 17...

Page 19: ...Page 19...

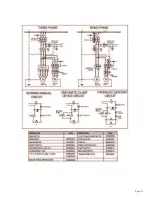

Page 20: ...Page 20 11 0 DRAWINGS SCHEMATICS 11 1 ELECTRICAL SCHEMATIC...

Page 21: ...Page 21...

Page 22: ...Page 22 11 2 MACHINE EXPLODED VIEW...

Page 23: ...Page 23...