Page 10

7.0 TROUBLESHOOTING/CORRECTIVE MAINTENANCE

PROBLEM

POSSIBLE CAUSES

The machine does not start.

Check that the main switch is connected to the power supply.

Motor fuse has blown.

2A fuse has blown.

The rear guard has not activated the safety micro-switch, or this is not

working properly.

Check the operating contactor, start-up control and transformer.

Bad quality or out-of-square cut.

Tension too low or too high. See Section 5.3

Condition of the cutting saw.

Coolant liquid used. We recommend pure, synthetic coolant

mixed 7 to 1 with water.

Condition of the blade guide plates.

Guide adjustment. See Section 7.1

Excessive wear on blade.

Tension too low or too high. See Section 5.3

Guide plates worn.

Excessive pressure from upper plate. See Section 7.1

Downwards feed in high or batch cutting.

Quality or pitch of blade unsuitable for the material or section to be

cut.

Coolant liquid used. We recommend pure, synthetic coolant mixed 7

to 1.

Noises when saw rotates.

State of belt guides. See Section 7.2

Excessive tension in cutting saw.

Bearings no. 26, 46 Figure 10.3

State of the cutting blade.

The pressure gauge does not

Top up with hydraulic oil (viscosity 32); to do so, the pressure gauge

reach 100 bars.

must be removed.

Check for oil leaks. State of internal flanges.

Tensing mechanism. Flywheel and bearing.

Summary of Contents for SU-280

Page 1: ...Page 1 MODEL SU 280 BAND SAW PRINTED JULY 2013...

Page 5: ...Page 5 3 2 SELECTION OF THE BAND SAW...

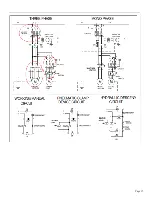

Page 16: ...Page 16 11 0 DRAWINGS SCHEMATICS 11 1 ELECTRICAL SCHEMATIC...

Page 17: ...Page 17...

Page 18: ...Page 18 11 2 MACHINE EXPLODED VIEW...

Page 19: ...Page 19 11 3 HYDRAULIC DESCENT EXPLODED VIEW...

Page 20: ...Page 20...