Page 11

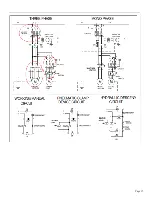

7.1 ADJUSTMENT OF CUTTING BLADE GUIDES

In order to obtain a correctly squared cut, you must make sure that there is a distance of .035

thousandths of an inch (0.9 mm) between the side plates (3), so that they are all in contact with the blade.

To adjust this distance, follow the instructions given below:

1. Loosen screws (1)

2. Place a .035" (0.9 mm) gauge or sheet between the

plates and adjust the distance using the set screw (2).

The gauge must slide smoothly but without

wobbling. (If a gauge is not available, a piece of the

cutting blade from the machine may be used.)

The upper guide assembly may also be exerting excessive pressure on the cutting blade, resulting in a

widening at the upper edge. To prevent this, loosen the screws (6) and slightly raise the blade guide (7).

The guide must be positioned so that after rotating the saw when it is not in contact with any material,

the plate (4) must not exert any downward pressure on the cutting blade when at rest. (There should be a

clearance of .004 (0.1 mm) with the blade.)

7.2. CHANGING THE GUIDE PLATES

Over time, the side plates (3) and the upper plate (4) may need to be replaced. To do so, follow the steps

indicated below:

1.

Loosen the screws (1) on both sides of the guide and remover the guide plates.

2.

Tap the plate (4) through the hole (5) until it comes out of its housing.

3.

Fit the upper plate and then the side plates (3).

4.

Adjust the lateral clearance of the plates, as explained in the previous section, ADJUSTMENT OF

CUTTING BELT GUIDES.

Summary of Contents for SU-280

Page 1: ...Page 1 MODEL SU 280 BAND SAW PRINTED JULY 2013...

Page 5: ...Page 5 3 2 SELECTION OF THE BAND SAW...

Page 16: ...Page 16 11 0 DRAWINGS SCHEMATICS 11 1 ELECTRICAL SCHEMATIC...

Page 17: ...Page 17...

Page 18: ...Page 18 11 2 MACHINE EXPLODED VIEW...

Page 19: ...Page 19 11 3 HYDRAULIC DESCENT EXPLODED VIEW...

Page 20: ...Page 20...