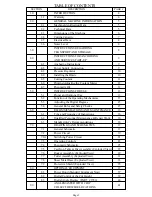

4.3 Pressure Regulator

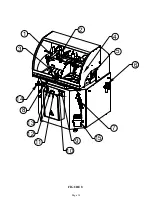

FIGURE 6

4.4 Installing The Blade

This machine uses a 600mm blade with a 50mm arbor.

1. Set the saw to ninety degrees and disconnect the power. Open the cabinet door and remove the

existing blade.

NOTE: The blade nut is right hand threaded.

2. Insert the rod provided with the machine into the blade flange (1) and loosen the blade nut (2) with

the wrench provided. The teeth on carbide blades are very sharp and we recommend using gloves

while changing blades. Remove the blade.

3. Check the blade flange and the blade seat for any chips or nicks before installing the new blade.

4. Install the new blade and the blade flange and blade nut. The saw blade rotates counter clockwise

Page 10

when facing the blade from the left side of the machine.

The air inlet location is shown below. The air regulator must be set at 6.5 to 7.2 Bar (95 to

105 PSI). The red knob on top is used to turn the air supply on or off.

There is another smaller regulator on the front left of the saw that regulates the air pressure

to the horizontal clamps. It should be set at 2-3 bar (30-45 psi). Maximum is 4 bar (60 psi).

REGULATOR FOR

HORIZONTAL CLAMPS

FILTER

REGULATOR

COMPRESSED

AIR INLET

ATTENTION: The incoming air pressure must be between 6.5 to 7.2 Bar (95 to 105 PSI ).

If pressure is too low it can affect the accuracy and consistency of parts.

ON/OFF

KNOB

PRESSURE

ADJUSTMENT

KBOB

Summary of Contents for SUP-600-NF

Page 1: ...You have downloaded a manual for our MODEL SUP 600 NF PRECISION MITER UP CUT NON FERROUS SAW...

Page 3: ...www scotchman com SUP 600 NF SAW FIGURE 1 Page 2...

Page 9: ...2 4 Cutting Capacity FIGURE 3 Page 7...

Page 16: ...FIGURE 8 1 2 3 4 5 6 7 9 10 14 13 12 11 Page 14 8 15...

Page 20: ...FIGURE 10 Filter Regulator Lubricator has a 1 4 BSPT Thread Page 18...

Page 26: ...Page 24 FIGURE 13 19 P N 677 LEGEND PLATE 1...

Page 40: ...Page 38 FIGURE 20 14 13 12 11 10 9 8 7 6 15 1 2 5 4 3...

Page 44: ...Page 42 FIGURE 23...