5. INSTRUCTIONS FOR USE

5.1 Proper and Improper Use

This is a semiautomatic cut-off machine especially designed for cutting non-ferrous profiles. The use

of the machine for cutting other materials is hereby prohibited. Such use may cause damage to the

machine and put the health and safety of the worker at risk.

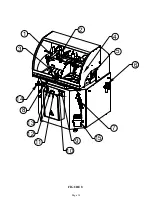

5.2 Function of the Operating Mechanisms

1. Horizontal clamps

2. Vertical clamps

3. Lever turn disc

4. Protective shield

5. M-10 x 40 lever

6. reg manometer

7. Clearing gun with hose

8. Advanced regulator 3/8"

9. Raise blade, green button

10. Two position selector

11. Green indicator light

12. Saw blade on-off

13. Emergency stop

14. Pressure regulator for horizontal clamps set at 2-3 Bar

DANGER: Always work with the protective shield lowered.

DO NOT DISCONNECT ANY SAFETY DEVICES!

NOTE: The clamping cylinders should not be used with the rod completely extended. The stress

produced when the rod of the cylinder is extended completely will reduce the life of the cylinder.

It should be at a distance of 1-1/4" to 1-1/2" (30-40 mm) from the material that's being clamped.

Page 13

DANGER: We are not responsible for any possible accident caused by

the failure to comply with the aforementioned provision.

15. Coolant reservoir.

Summary of Contents for SUP-600-NF

Page 1: ...You have downloaded a manual for our MODEL SUP 600 NF PRECISION MITER UP CUT NON FERROUS SAW...

Page 3: ...www scotchman com SUP 600 NF SAW FIGURE 1 Page 2...

Page 9: ...2 4 Cutting Capacity FIGURE 3 Page 7...

Page 16: ...FIGURE 8 1 2 3 4 5 6 7 9 10 14 13 12 11 Page 14 8 15...

Page 20: ...FIGURE 10 Filter Regulator Lubricator has a 1 4 BSPT Thread Page 18...

Page 26: ...Page 24 FIGURE 13 19 P N 677 LEGEND PLATE 1...

Page 40: ...Page 38 FIGURE 20 14 13 12 11 10 9 8 7 6 15 1 2 5 4 3...

Page 44: ...Page 42 FIGURE 23...