Page 16

6.0 RECOMMENDATIONS AND MAINTENANCE

6.1 Type and Frequency of Inspections

The operator’s knowledge of the machine is one of the best ways of daily control of any possible problem.

If any failure is detected, work must be stopped and qualified personnel must be informed immediately.

NOTE: Always clean the machine and the work area at the end of the work day.

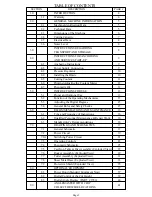

MAINTENANCE TABLE

LUBRICATION POINTS

Turret travel rail

Rocker bearings

Pneumatic cylinder

TYPE OF GREASE/OIL

SAE 30 lubricating oil

Roller bearings grease

AW 32

CHECK POINTS

Machine cleaning

Condition of the transmission belt

FREQUENCY

WEEKLY

ANNUALLY

ANNUALLY

FREQUENCY

DAILY

WEEKLY

6.2 Qualified Personnel for Maintenance and Repair Work

All repairs shall be made exclusively by qualified personnel. Always use original replacement parts.

If not, the machine may be damaged or the user may be injured.

6.3 Manufacturer's Recommendations

In the event that the machine is broken down or the saw blades must be replaced, place a padlock

on the protection switch and place the keys under the care of qualified personnel.

Before working on any electrical devices, disconnect the plug from the power supply.

If extension cords are used, ensure that the cable has the appropriate rating for the power of

the machine.

Whenever any part has to be replaced, use an original replacement part and use the oil

recommended by the manufacturer.

Once a week, all of the chips in the saw should be thoroughly cleaned out. This includes blowing

out the chips in the motor fan guard.

Once a month, check the motor belt for any wear.

Once a month, grease the bearing hub.

NOTE: In case of any doubt or problem, do not hesitate to consult the manufacturer.

ATTENTION: The manufacturer hereby guarantees the supply of each of the parts or components

for at least two years from the manufacturing date of the machine.

►

►

►

►

►

►

►

►

►

Summary of Contents for SUP-600-NF

Page 1: ...You have downloaded a manual for our MODEL SUP 600 NF PRECISION MITER UP CUT NON FERROUS SAW...

Page 3: ...www scotchman com SUP 600 NF SAW FIGURE 1 Page 2...

Page 9: ...2 4 Cutting Capacity FIGURE 3 Page 7...

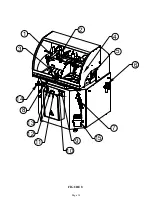

Page 16: ...FIGURE 8 1 2 3 4 5 6 7 9 10 14 13 12 11 Page 14 8 15...

Page 20: ...FIGURE 10 Filter Regulator Lubricator has a 1 4 BSPT Thread Page 18...

Page 26: ...Page 24 FIGURE 13 19 P N 677 LEGEND PLATE 1...

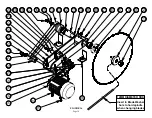

Page 40: ...Page 38 FIGURE 20 14 13 12 11 10 9 8 7 6 15 1 2 5 4 3...

Page 44: ...Page 42 FIGURE 23...