Thermostatic Expansion Valve

1. Before replacing this valve, be certain that the

valve is the cause of the problem, and cannot be

adjusted.

2. Remove the top, service and front panels.

3. Discharge and recover the refrigerant.

4. Locate the TXV bulb (on the suction line),

remove the clamps and bulb from the tube.

5. With the refrigeration system open, unsweat the

TXV from the tubing.

6. Place the new TXV in position.

7. Wrap the new TXV body with wet rags. Do not

get any moisture in the valve.

8. Carefully braze the valve to the tubing. Examine

the joints, if they look good proceed to the next

step, if not, re-do them.

9. Install a new dryer, and braze it in place also.

10. Reattach the TXV bulb to the suction line in the

same place as the old one.

11. Evacuate the system to 200 microns.

12. Weigh or measure the nameplate charge into

the receiver.

13. If the machine has been off on the breaker

there may be refrigerant trapped in the oil of the

compressor, so do not restart until the compressor

has been warmed by the crankcase heater for 12

hours. If the compressor was warm throughout the

replacement process, the ice machine may be

restarted without waiting to re-warm the

compressor.

Hot Gas or Liquid Line Valve.

1. Before replacing this valve, be certain that the

valve is the cause of the problem.

2. Remove the top, service and front panels.

3. Discharge and recover the refrigerant.

4. Unplug the coil of the valve.

5. With the refrigeration system open, unsweat the

valve from the tubing.

6. Place the new valve in position.

7. Wrap the new valve body with wet rags. Do not

get any moisture in the valve.

8. Carefully braze the valve to the tubing. Examine

the joints, if they look good proceed to the next

step, if not, re-do them.

9. Install a new dryer, and braze it in place also.

10. Plug the power cord back onto the coil.

11. Evacuate the system to 200 microns.

12. Weigh or measure the nameplate charge into

the receiver.

13. If the machine has been off on the breaker

there may be refrigerant trapped in the oil of the

compressor, so do not restart until the compressor

has been warmed by the crankcase heater for 12

hours. If the compressor was warm throughout the

replacement process, the ice machine may be

restarted without waiting to re-warm the

compressor.

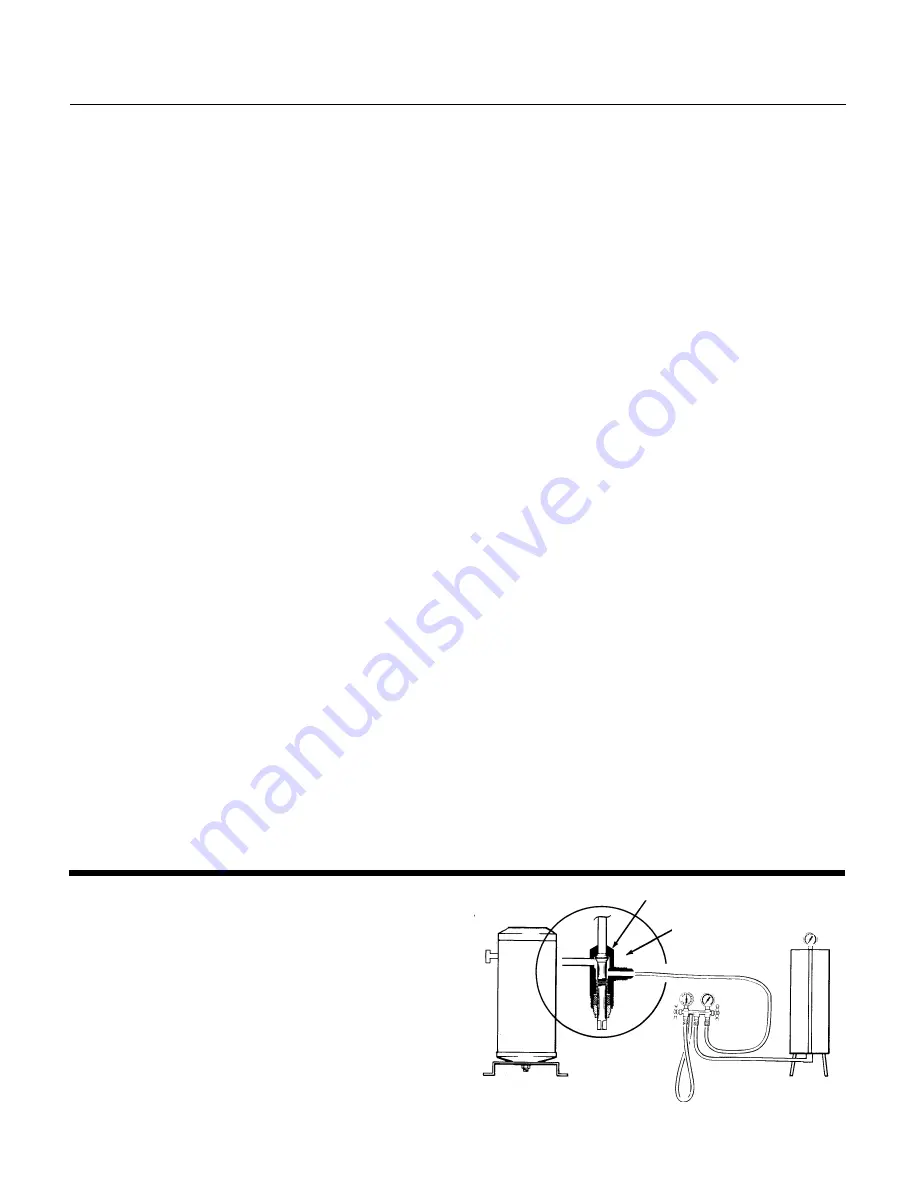

FRONT SEATED VALVE

SERVICE PORT

Refrigerant:

NO liquid refrigerant may be put into this system

anywhere except the receiver. DO NOT use the

access valves at the front of the machine for

weighing in the charge: use the “king” or receiver

service valve. All liquid HP62 must be weighed

into the receiver through the “front seated”

receiver outlet service valve.

REMOVAL AND REPLACEMENT

CME500R

March 1994

Page 26