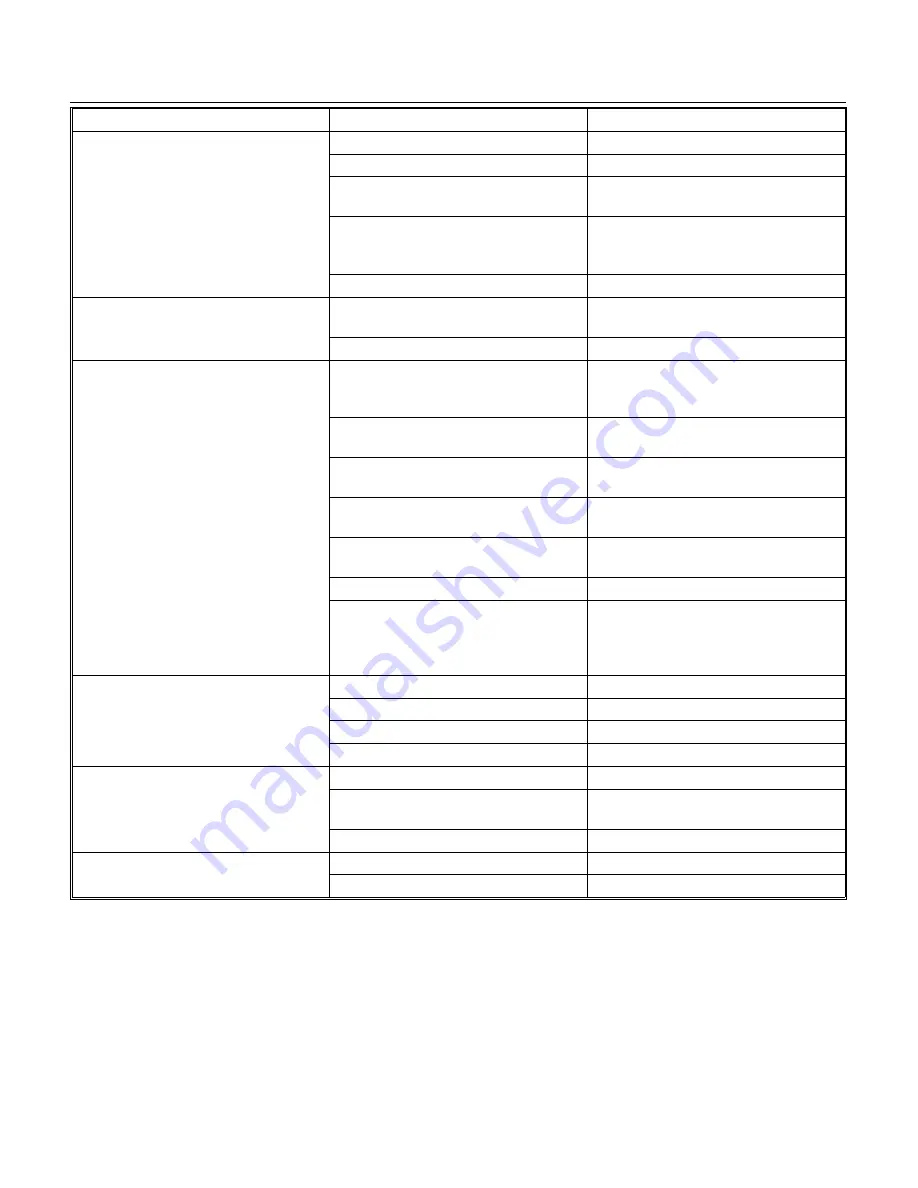

SERVICE DIAGNOSIS: Refrigeration and/or Mechanical

SYMPTOM

POSSIBLE CAUSE

PROBABLE FIX

Poor harvest

Too short harvest time

Check and adjust harvest time

Restriction of incoming water

Check supply, filter, strainer and valve

Hot gas valve does not open

Check for power to the coil, check for

not opening, replace

Not enough refrigerant

Locate leak, repair, replace drier,

evacuate and weigh in nameplate

charge.

Cube size too small

Adjust with cube size control

Unit cycles off during freeze or

harvest

Hi temperature switch opens and

closes

Hot gas valve leaks thru, replace it

Loose connection on PC board

Check and replace P C board

Low capacity

High head pressure, from dirty

condenser, faulty fan motor, or fan

control

Clean condenser, repair fan motor or

control

Non condensable gas in the system

Purge system, evacuate and weigh in

nameplate charge

Poor air circulation or extreme hot

location

Relocate the cabinet; or provide

ventilation

Overcharge of refrigerant

Evacuate and weigh in nameplate

charge

Cube size too big, unit runs out of

water before harvest

Adjust cube size control

Inlet water valve leaks thru

Replace valve

Hot gas valve leaks thru

At the end of the freeze cycle there

should be frost on the evaporator end

of the hot gas tubes, if not replace the

hot gas valve

Unit runs out of water

Reservoir leaks

Repair leak

Inlet water valve restricted

Clean or replace valve

Short harvest cycle

Adjust timer

Water pressure too low

Check supply

Unit shuts off before bin is full

Something blocking transducer

Remove blockage

Transducer is wet

Remove transducerand shake screen

dry.

Control set on partial

Set control to full.

Unit does not shut off

Ice level control failiure

Check circuit, see next page.

Timer stuck; does not turn

Replace timer

CMS1202

September 1993

Page 21