N0922L, N1322L, F1222L, F1522L

Remote Low Side Service Manual Includes Prodigy Plus

December 2014

Page 29

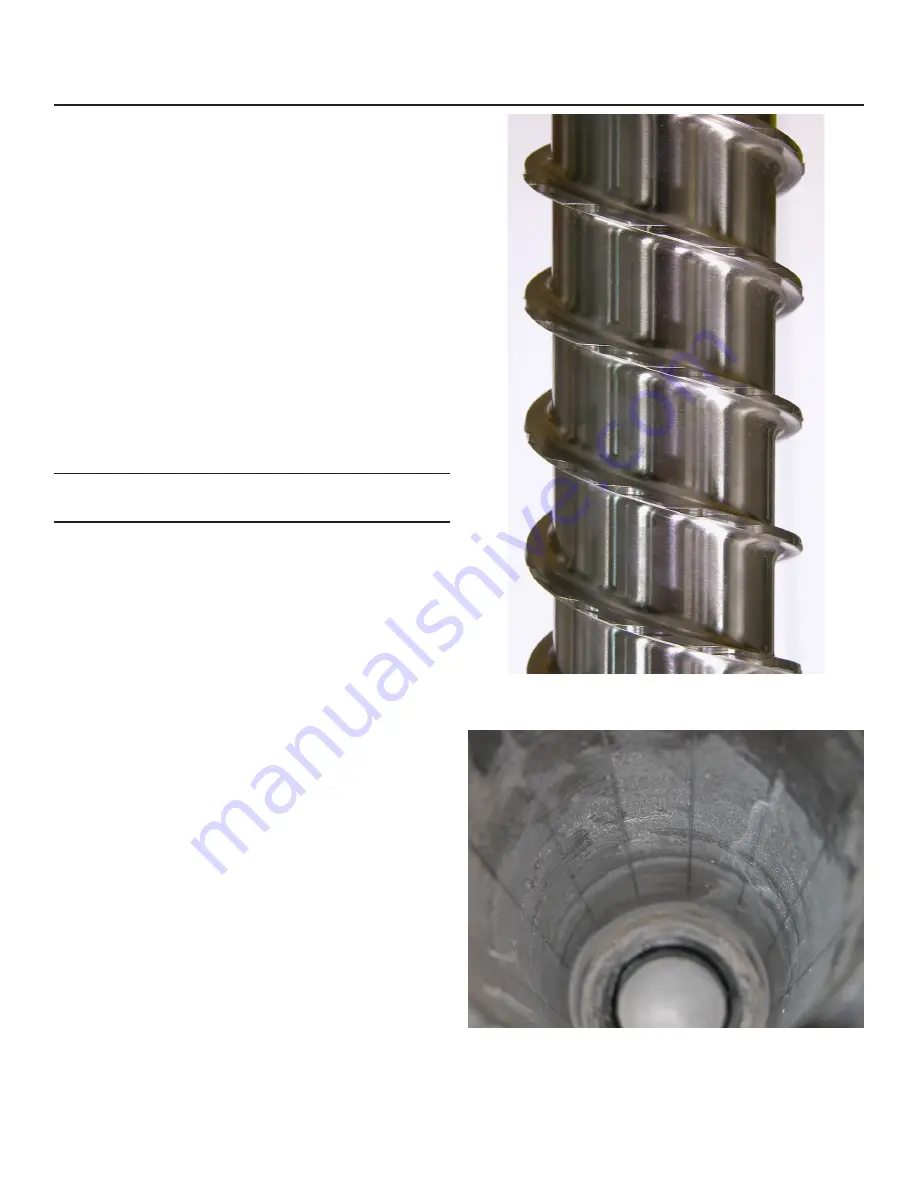

Auger and Evaporator Inspection

The auger must be carefully inspected for wear and

scale. There are also wear areas like the top bearing

surface and the edges of the flights. The edges of the

auger have horizontal serrations and highly machined

areas in between. If the auger has contacted the

evaporator wall, it will have very rough flight edges

and should be replaced.

Scale forms on the auger during normal ice making.

If scale is still on the auger after cleaning in the

ice machine, the scale can be removed using ice

machine cleaner and a nylon scrub pad.

Inspect the auger, the critical areas of the auger are:

1. The auger body. It should be clean and shining.

Sometimes an auger will appear clean when wet, but

after it is dry it will be seen to be stained. Scrub the

auger with ice machine cleaner and hot water.

Caution: Ice machine cleaner is an acid. Handle it with

extreme care, keep out of the reach of children.

2. The water seal area. Because the auger has been

removed, the water seal will have to be replaced.

Remove the water seal top half from the auger, and

remove any sealant or debris from the shoulder of the

auger where the water seal was.

Inspect the evaporator's interior. The interior is

stainless steel that should be bright and shiny

when dry. If it isn't the scale on the surface must be

removed. To remove scale:

1. Remove the water seal; it will have to be replaced.

2. Use a brass wire brush and scrub the interior of the

evaporator vertically to remove any scale.

3. Clean up any debris from the top of the gear

reducer.

Example of a Clean Auger

Example of Scale Build Up on Evaporator Wall