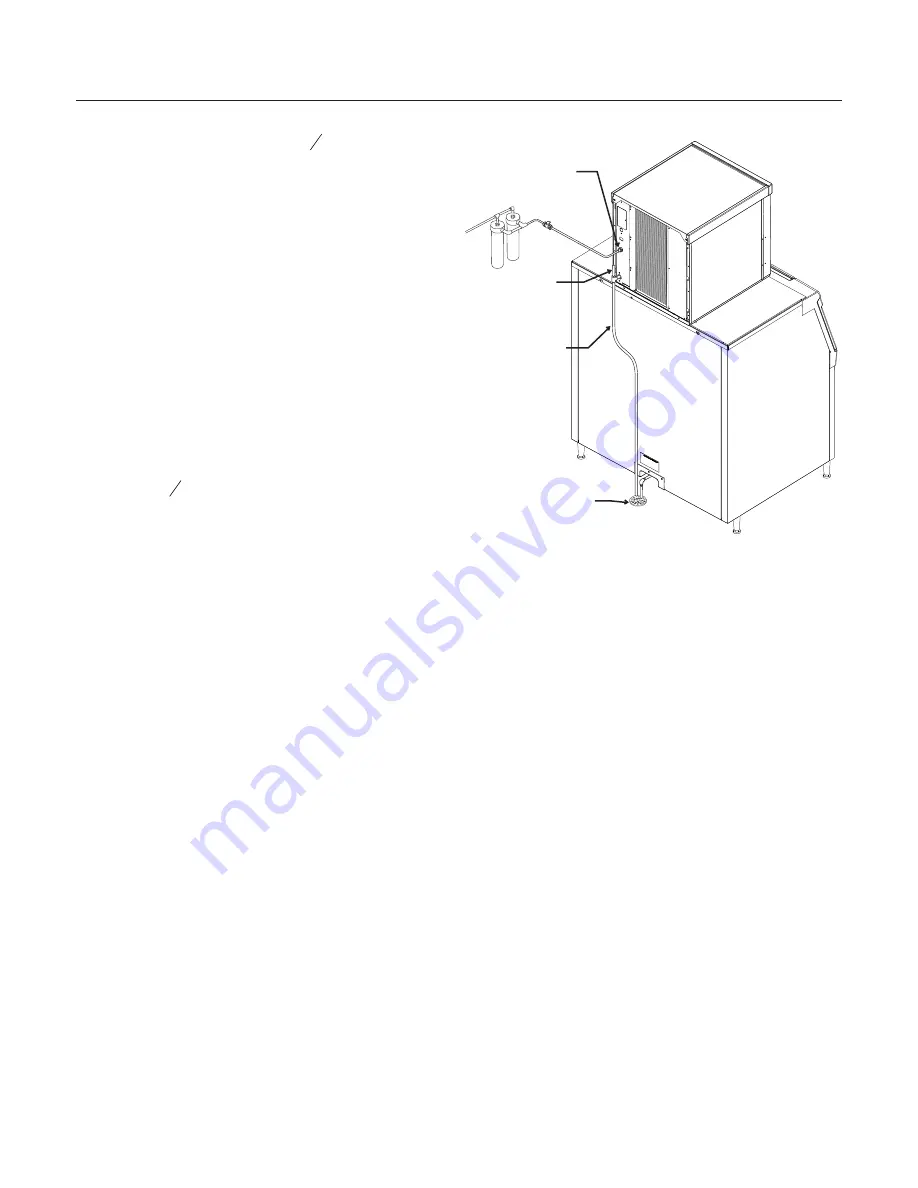

Water Supply and Drains

The water supply for ice making must be cold,

potable water. There is a single

3

8

” male flare

potable water connection on the back panel.

Backflow

The design of the float valve and reservoir prevents

potable water backflow by means of a 1" air gap

between the reservoir's maximum water level

and the float valve water inlet orifice.

Drain

There is one ¾” FPT condensate drain fitting at

the back of the cabinet.

Attach Tubing

Connect the potable water supply to the potable

water fitting,

3

8

” OD copper tubing or the equivalent

is recommended.

Water filtration is recommended. If there is an

existing filter, change the cartridge.

Drains - use rigid tubing: Connect the drain tube to

the condensate drain fitting. Vent the drain.

Do not Tee ice machine drains into the drain tube

from the ice storage bin or dispenser. Back ups

could contaminate and / or melt the ice in the bin or

dispenser. Be sure to vent the bin drain.

Follow all local and national codes for tubing, traps

and air gaps.

August 2011

Page 7

NB0622, NB0922, FB1222, NB1322

Installation and Use

Air Cooled Plumbing

Water Inlet

Condensate

Drain

Building Drain

Drain Vent