Inspection: Auger

The auger is made of stainless steel. It has a

polished surface that may be either shinny or dull,

but must be smooth. After removal, allow the auger

to dry to inspect for scale. If mineral scale is found

on the auger’s surface, clean off the auger with ice

machine cleaner and a scrubbing pad.

Remove the water seal and clean off the shoulder

of the auger.

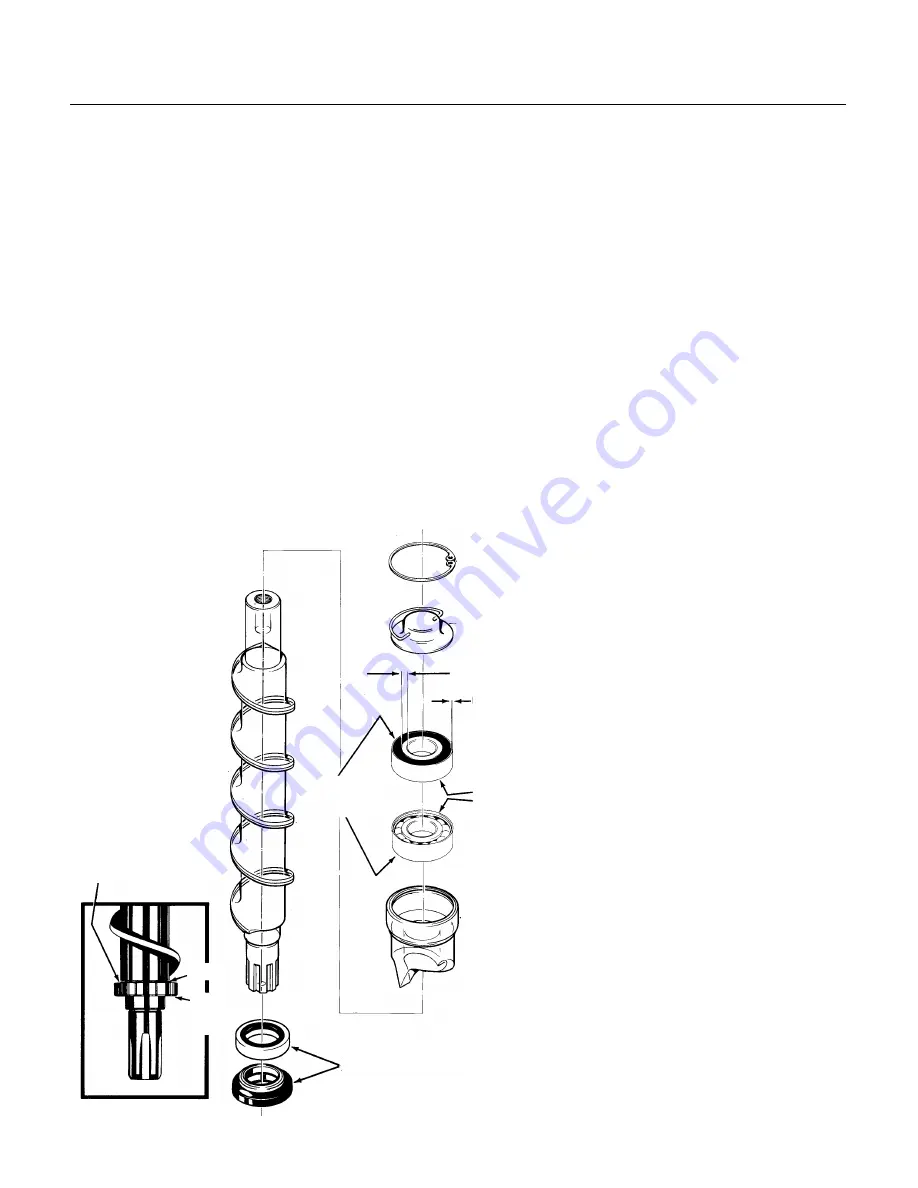

Bearings: The top bearing should spin freely with

no rough spots. If it feels rough when spun by

hand, replace it. There should be minimal rust or

dirt. If in doubt, replace the bearing.

Note: The top bearing used in the FDE470 is a

"directional" bearing. Note which way the inner

race is configured and install into the breaker. The

breaker is also available as a replacement part

with the top bearing already installed.

The bottom bearing must be removed from the

evaporator when replacing the water seal.

Remove bin cover.

To replace the water seal:

1. Remove old rotating half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shoulder of the auger where the rotating half of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auger, rubber side toward

the auger. Push up until seated against the

sealant. Do not allow any sealant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the bottom of the evaporator

until the bottom of the seal is inside the evaporator

about 1/4".

5. Push the bottom bearing against the water seal

until the bottom bearing is inside the evaporator

about 1/16".

6. Replace the evaporator on the adapter, and

re-attach the stand using the original bolts.

7. Attach the auger to the top bearing

and breaker.

8. Return the auger to the evaporator

and slide it down until the splines touch

the coupling.

9. Rotate the auger until the coupling

splines align with the auger.

10. Push the auger down, and rotate

the breaker until the screw holes line

up with the pilot holes in the evaporator.

11. When the auger is completely

seated, reinstall the breaker screws.

12. Replace permagum and foam top.

13. Switch on the water supply.

14. Check bin cover for electrical

grounds and switch on the electrical

power.

15. Observe operation. The unit should

make minimal noise while producing

ice. Catch first 2 minutes of ice and

discard it.

16. Replace the bin cover and all

panels.

Sealant

Here

Water Seal

Open

Sides

Inner Race

Wider on Top

Side

Outer

Race

Rubber

Smooth

Side

Remove the three bolts holding the

evaporator to the gear motor adapter and lift

the evaporator up

slightly. Tap the water

seal and bottom

bearing out from the

top down. Check the

bottom bearing the

same way as the top.

Replace the water

seal and install a

new bearing set if

needed.

FDE470

August 1994

Page 16

Summary of Contents for FDE470

Page 28: ...FDE470 August 1994 Page 28 ...