Refrigeration System

This ice machine uses R-134a as the

refrigerant. This refrigerant has no chlorine,

and therefore requires polyolester type

refrigerant oil. This oil requires specific service

procedures.

General Service

A HFC type liquid line drier is required. “Standard”

driers may not take out enough moisture and may

affect the oil additives.

The time that the refrigeration system is open to

the air must not exceed 15 minutes. The oil will

rapidly absorb moisture from the air, and the

contact time must be kept to a minimum.

A special or very sensitive electronic leak detector

will be needed to locate refrigerant leaks. Many are

on the market that will sense R-134a.

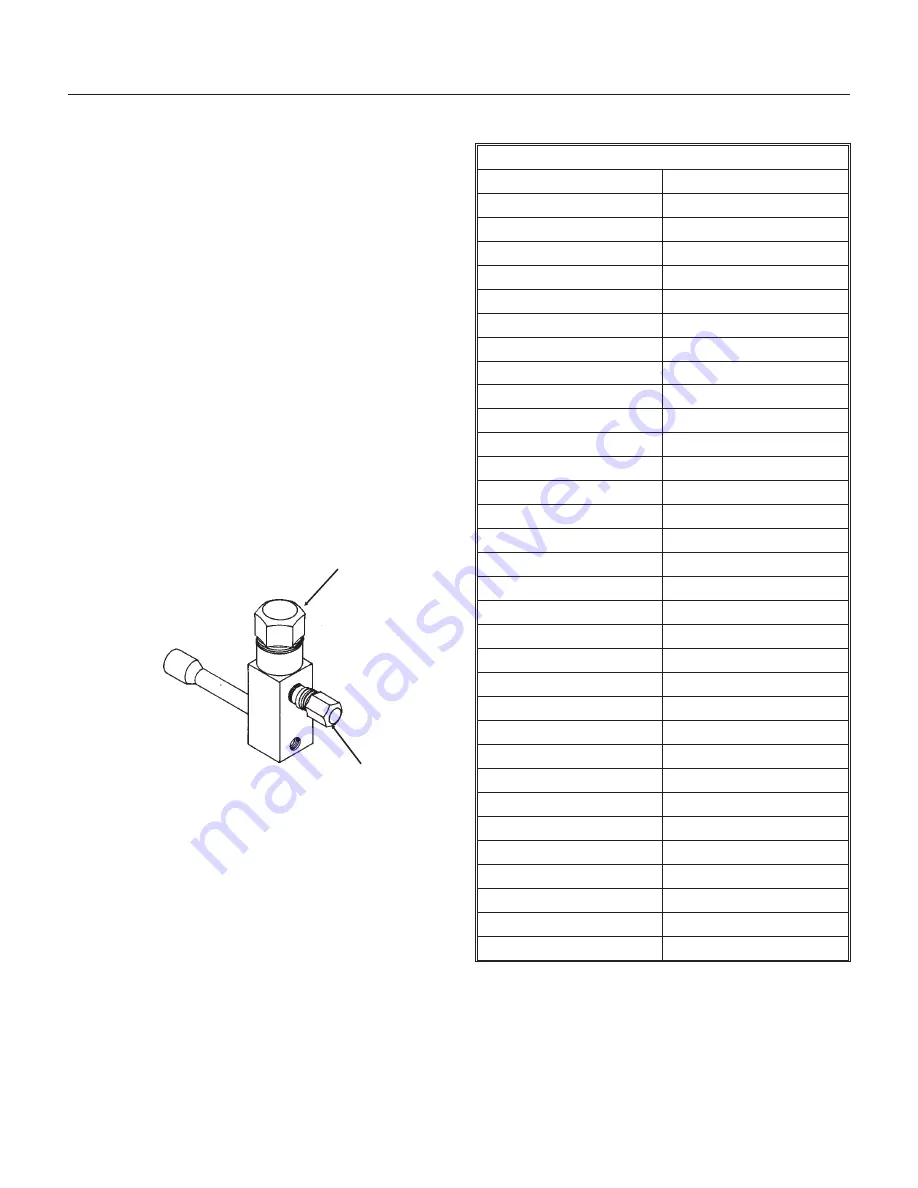

The access valves must be in the closed position

before the hose caps are removed. Do not remove

the hose caps before checking the position of the

valve. Use a 3/16" allen wrench to open and close

the valve.

As with any other refrigerant, do not place

pressurized air or oxygen into the refrigeration

system.

Note: The refrigeration system uses an HFC type

refrigerant and MUST use an HFC type drier.

Evacuation to 300 microns is recommended.

FDE474

March 2000

Page 27

Stem Cap

Torque to 8-12 ft. lb.

Fitting Cap

Torque to 7-12 ft. lb.

Access Valve

Torque Stem to

6-8 ft. lb.

Temperature Pressure Chart, Selected Points

Temperature in

0

F.

PSIG of R-134a

-10

2.0

-6

3.7

-4

4.6

-2

5.5

0

6.5

1

7.0

2

7.5

3

8.0

4

8.6

5

9.1

10

12.0

12

13.2

14

14.4

16

15.7

18

17.1

20

18.4

25

22.1

30

26.1

31

26.9

32

27.8

33

28.6

34

29.5

35

30.4

40

35.0

45

40.0

50

45.4

75

78.7

90

104.3

110

146.4

120

171.1

130

198.7

150

262.8