REMOVAL AND REPLACEMENT: Bearing And Breaker

Note: Removal of the auger, water seal,

evaporator and gearmotor must begin at the

top of the assembly.

To Remove the Breaker Bearing Assembly:

//////////////////////////////WARNING////////////////////////////

Disconnect the electrical power to the

machine at the building source BEFORE

proceeding with any repair.

//////////////////////////////////////////////////////////////////////////

1. Remove panels and disconnect electrical

power.

2. Unscrew three studs and remove ice chute

cover.

3. Unscrew and remove ice sweep.

4. Remove insulation halves from outside of

ice chute, loosen band clamp under ice chute,

lift up and remove ice chute.

5. The breaker may be removed from the

auger and evaporator without disturbing the

auger.

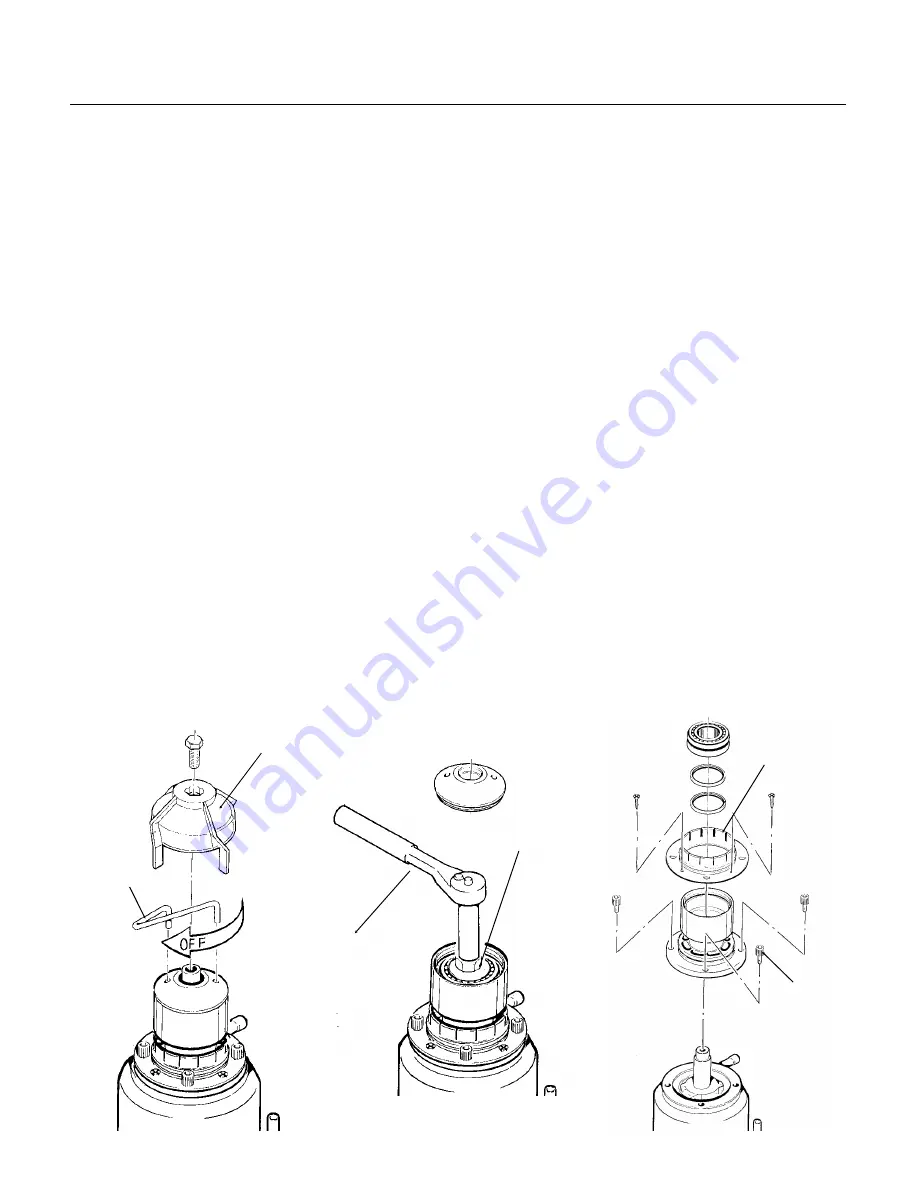

a. Use spanner wrench and unscrew breaker

cover from breaker (left hand threads)

b. Unscrew auger stud from top of auger.

c. Unscrew 4 allen head cap screws holding

breaker to evaporator.

d. Lift up, and remove breaker/bearing

assembly from auger & evaporator.

6. Service the bearing. Check for rust, rough

spots and damage.

a. The bearing is pressed into the breaker, to

remove the bearing and replace it an arbor

press is needed.

b. Replace lower seals before installing new

bearing in breaker.

Note: seals must be pressed in with a tool

pushing against the outer edge only, they will

not install by hand.

Replace parts as required. Re-grease bearing

with Scotsman part no. 19-0609-01 bearing

grease. Replace top seal, and check the

o-rings, replace if cut or torn.

7. Reverse to reassemble: specific tools and

materials are required to install properly.

a. Add food grade grease such as Scotsman

part number 19-0569-01 to the seal area

before installing on the auger.

b. Check the seal to shaft areas for cuts, or

rough spots: none are permitted.

ICE

SWEEP

SPANNER

WRENCH

AUGER

STUD

ALLEN

SCREWS

SLOTTED

COLLAR

Step 5-a

Step 5-b

Step 5-c and Step 6

FM1200R

November, 1988

Page 31