REMOVAL AND REPLACEMENT: Refrigeration System

General:

••

Scotsman recommends that any work on the

refrigeration system only be done when it is

certain that the system needs repair.

••

The access valves are at the front of the

cabinet. To use them, remove the cap from the

valve ports and the cap from the top of the

valve body. Attach gauge manifold and then

use a 3/16" allen wrench to loosen the valve.

Although pressure readings may be taken with

the valve cracked open, several turns are

required to completely open the valve.

Close

valve and replace caps when the job is

finished.

••

Refrigerant should not be added except as a

way to determine the proper operation of the

product. If the system was low on refrigerant,

there is a leak, and it must be found and

repaired.

••

Although this system uses R-22, it must not

be vented to the atmosphere.

••

This system has a critical charge, it must be

recharged with the correct amount of

refrigerant as listed on the nameplate of the

ice machine, or performance will suffer.

••

Anytime the refrigeration system has been

opened, the dryer should be replaced.

••

When brazing the tubing connections to the

thermostatic expansion valve, the component

must be protected by heat sink material.

Specifically:

Recover, reclaim or recycle refrigerant. Although

the method chosen is up to the service

company, Scotsman recommends reclaim.

There are various mechanical devices that may

be used to recycle refrigerant at the field level,

however, Scotsman requires that any refrigerant

placed into a Scotsman ice machine meet ARI

spec 700-88. Reclaim programs are available

thru most refrigerant wholesalers.

Use conservation minded service procedures:

••

Refrain from checking refrigeration pressures

without reason. There are many ways to

determine the proper operation of a

Scotsman ice machine without using

refrigerant gauges. Visual inspection of the

water system, amp draw, voltage, and other

techniques will lead to proper diagnosis.

••

If gauges must be used, do not always check

the high side pressure. If the condenser is

clean and seems to be operating correctly, it

most likely is. The low side pressure is much

more important on an ice machine than is the

high side.

••

If gauges must be used, use very short

hoses. Minimal refrigerant discharged into the

hoses equals minimal refrigerant discharged

into the air.

If using recycled refrigerant, it must meet ARI

spec 700-88 or have been cleaned by a

machine capable of attaining ARI spec 700-88.

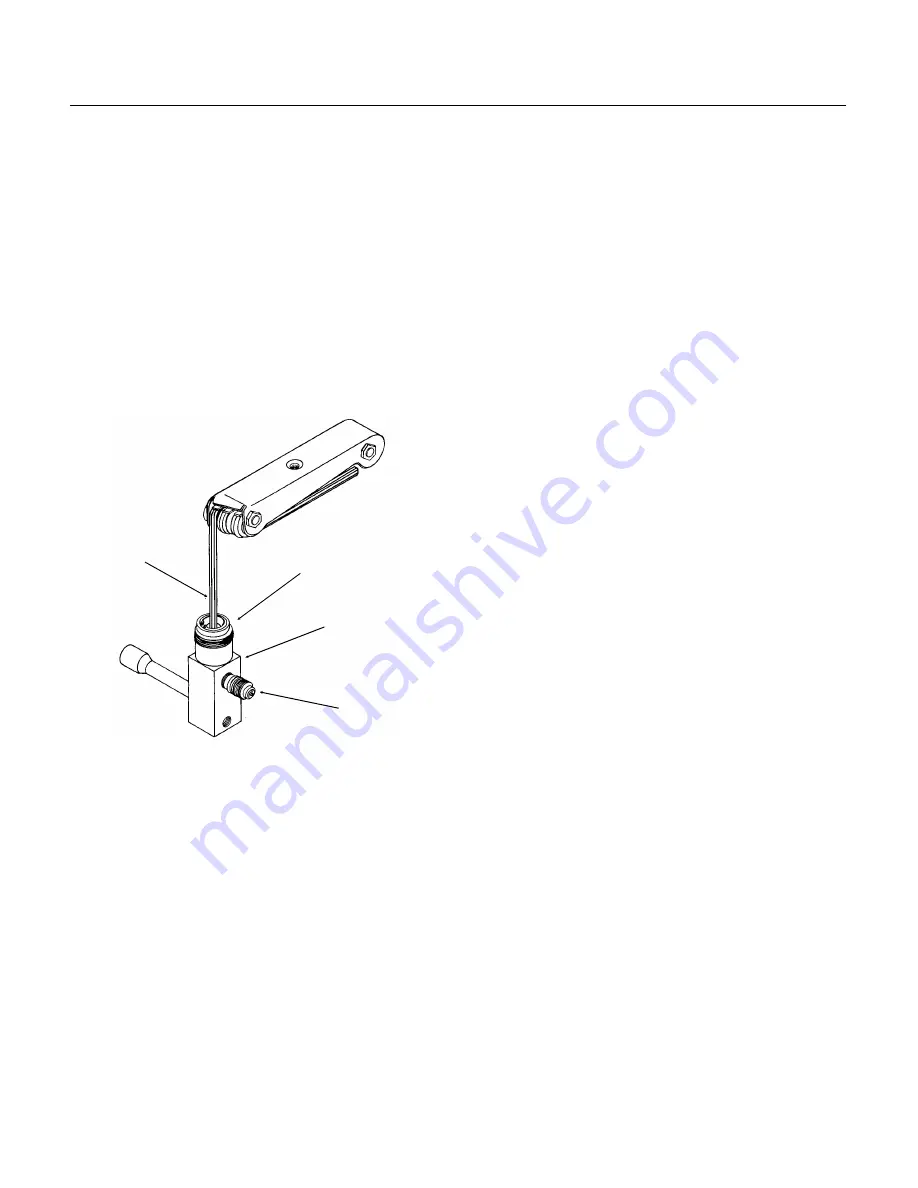

ACCESS

VALVE

ALLEN

WRENCH

Torque Stem

to 6-8 ft. lbs.

Torque Cap

to 8-12 ft. lbs.

Torque Cap

to 7-12 ft. lbs.

FM1202R

November 1992

Page 33