///////////////////////////WARNING/////////////////////////////

Disconnect electrical power before

beginning.

//////////////////////////////////////////////////////////////////////////

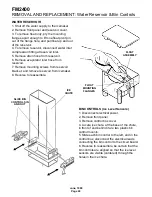

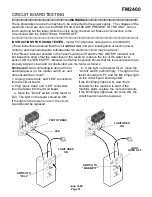

1. The bin control uses devices that sense

light, therefore they must be kept clean

enough so that they can “see”. At least twice a

year, remove the bin control sensors from the

base of the ice chute, and wipe the inside

clean, as illustrated.

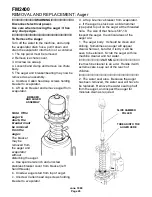

2. The ice machine senses water level by a

probe located in the water reservoir. At least

twice a year, the probe should be removed

from the reservoir, and the tip wiped clean of

mineral buildup.

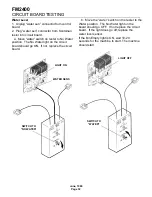

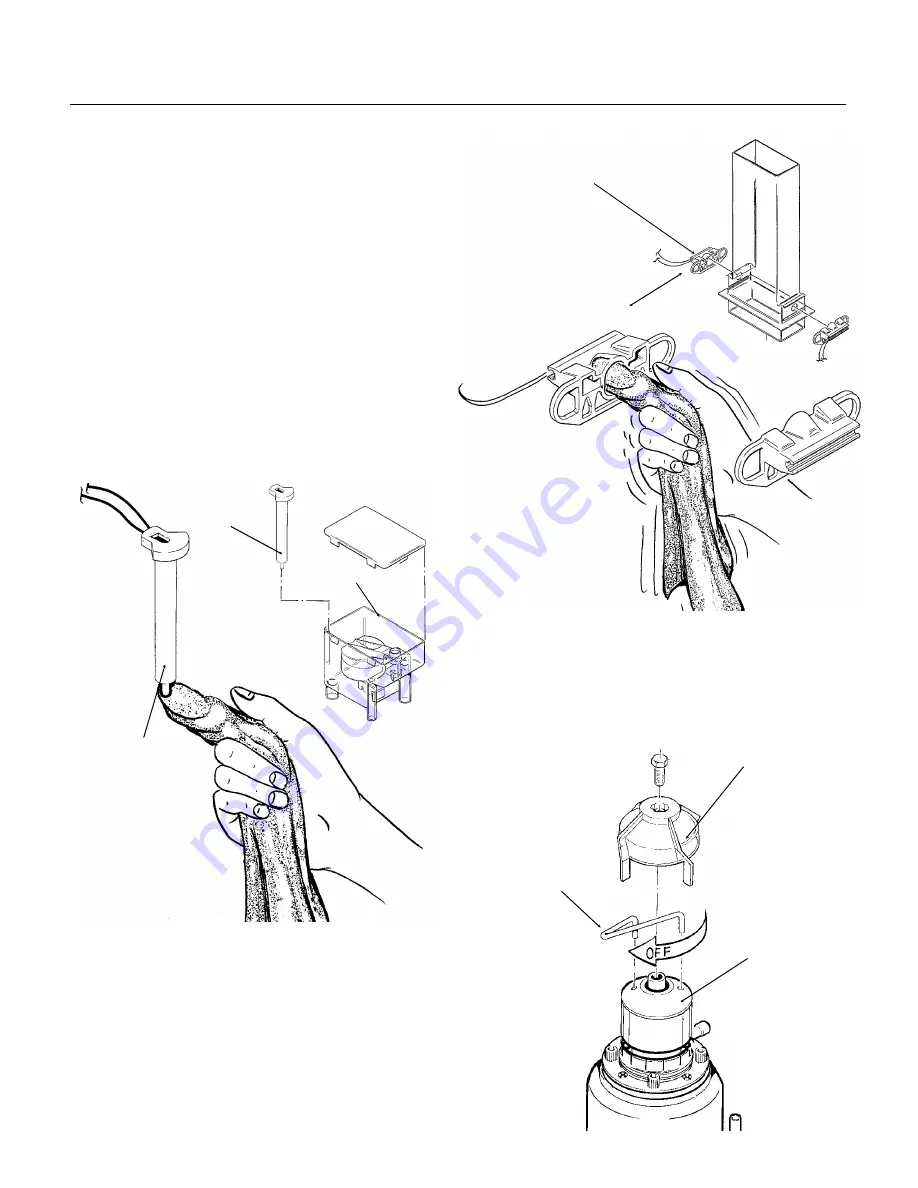

3. The bearing in the breaker should also be

checked at least two times per year.

A. Check the bearing by:

••

removing the ice chute cover

••

unscrewing the ice sweep

••

removing the water shed

••

using a spanner wrench and unscrewing

the breaker cover.

••

unscrewing the auger stud

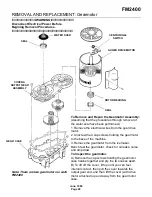

Inspect the assembly, looking for wear.

See Removal and Replacement to replace

bearing or seals. Reverse to reassemble.

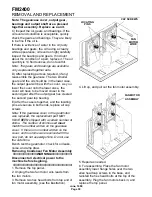

4. Check and tighten all bolts and screws.

CLEAN THE

WATER LEVEL

PROBE

PULL UP TO

REMOVE PROBE

RESERVOIR

///////////////////////////////////////////

CAUTION: THE TIP IS

MADE OF GLASS

//////////////////////////////////////////

ICE LEVEL SENSORS:

SLIDE TO REMOVE

CLEAN THE

LIGHT SENSORS

MAINTENANCE AND CLEANING

ICE SWEEP

SPANNER

WRENCH

BREAKER

COVER

The FM2400 is made up of two separate ice makers; to properly clean and maintain the FM2400,

these steps must be followed for both systems.

FM2400

June, 1989

Page 17