FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

Water Inlet

Air Cooled Models: The recommended water

supply is clean, cold water. Use 3/8" O.D.

copper tubing, and connect to the single 3/8"

male flare at the back of the cabinet. This

connection supplys water to both ice making

systems. Install a hand valve near the

machine to control the water supply.

Water Treatment: In most areas, a water filter

of some type will be useful. In areas where the

water is highly concentrated with minerals the

water should be tested by a water treatment

specialist, and the recommendations of the

specialist regarding filtration and/or treatment

should be followed.

Water Cooled Models: A separate 3/8" O.D.

copper line is recommended, with a separate

hand valve to control it. It is connected to a

single 3/8" FPT condenser inlet at the back of

the cabinet. This connection supplys water to

both water cooled condensers. The water

pressure to all lines must always be above 20

psig, and below 120 psig.

Drains

Air Cooled Models: There is one 3/4" FPT

drain for both ice making systems at the back

of the cabinet, the drain line is of the gravity

type, and 1/4 inch per foot fall is an acceptable

pitch for the drain tubing. There should be a

vent at the highest point of the drain line, and

the ideal drain receptacle would be a trapped

and vented floor drain. Use only 3/4" rigid

tubing.

Water Cooled Models: In addition to the

above mentioned drain, a separate condenser

drain must be installed. There is one drain for

both ice making systems. Connect it to the

1/2" condenser drain connection at the back of

the cabinet.

Storage Bin: A separate gravity type drain

needs to be run, similar to the air cooled drain.

Insulation of this drain line is recommended.

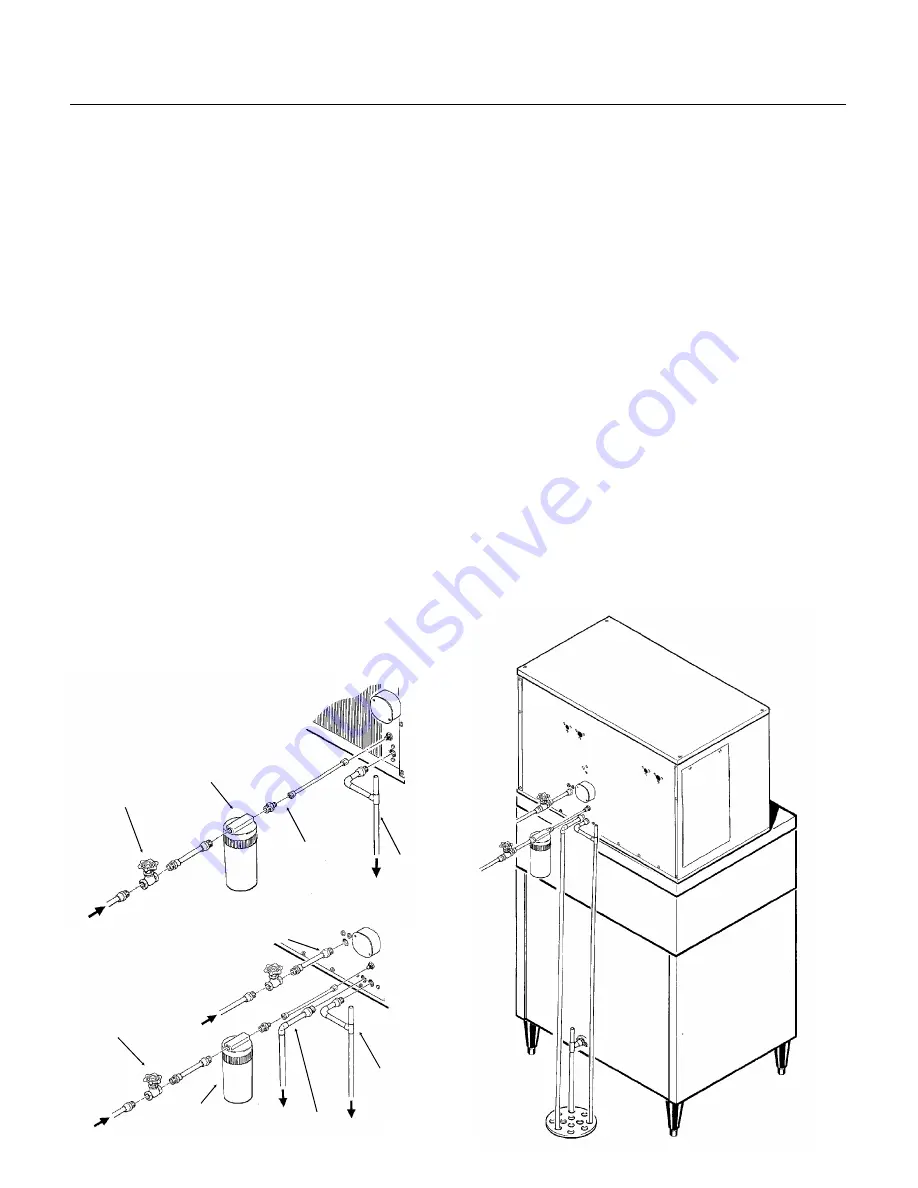

COMPLETE PLUMBING INSTALLATION, WATER

COOLED

WATER

COOLED

HAND

VALVE

CONDENSER

INLET

WATER

FILTER

CONDENSER

DRAIN

VENTED

DRAIN

AIR COOLED

MODELS

HAND

VALVE

FIELD

SUPPLIED

FILTER

WATER

INLET

VENTED

DRAIN

FM2400

June, 1989

Page 6