REFRIGERATION SYSTEM SERVICE

NME1854R & FME2404R

January 2000

Page 34

General: This ice machine uses R-404A refrigerant

and polyolester oil. Do NOT use mineral oil in this

refrigeration system.

·

When the system is serviced, a special liquid

line drier is required. It is included with

replacement compressors.

·

R-404A is not compatible with mineral oil so

these ice machines use Polyolester oil.

Polyolester oil absorbs water very easily. A

system opened for service must be re-sealed as

soon as possible (15 minutes maximum).

·

Special leak detection equipment is required to

locate small refrigerant leaks. Usually a leak

detector capable of detecting a Halongenated

refrigerant or HFC-134a will work. Check with

the leak detector manufacturer if in doubt.

·

Evacuate to 300 microns.

·

Liquid charge the system

Access Valves

: To use the access valves:

·

Remove the cap from the stem, use a 3/16"

allen wrench to check that the valve is

CLOSED. The remove the core cap.

·

Close the valve and replace the caps when

done. The valve must be closed and the caps

must be on or the valve will leak.

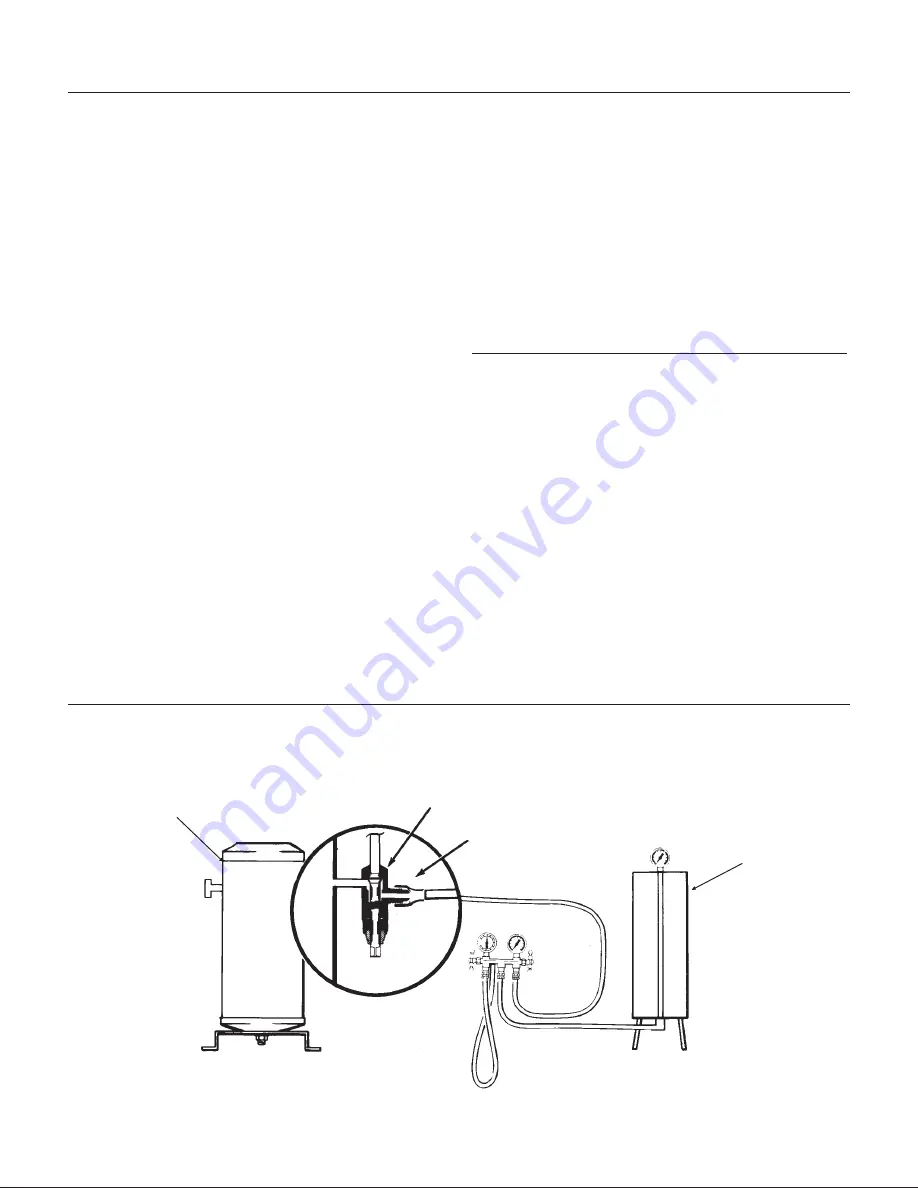

CHARGING PROCEDURES

Extra care must be taken when recharging this

remote system. No liquid refrigerant maybe placed

in the system at the compressor. DO NOT use the

valves at the front of the unit for weighing in the

charge. All liquid refrigerant must be weighed into

the receiver through the “front seated” king valve.

KING VALVE

SERVICE PORT

CHARGING

CYLINDER or

SCALE

RECEIVER

Head Pressure Control Valve

1. Purge system of refrigerant

2. Break off process tube on the top of the OLD

head pressure control valve.

3. Unsweat old valve from tubing.

4. Unsweat old dryer from tubing.

5. Install new valve in place, check for correct

connections and be sure the number on the side of

the valve is “180"

6. Wrap the new valve body in wet cloths to heat

sink the valve body.

7. Sweat in the new valve and the new dryer.

8. Evacuate the system, and weigh the nameplate

charge into the receiver.