Page 18

Page 18

When the temperature of the evaporator

serpentine drops to a pre-set value, the evaporator

sensor probe changes its electrical resistance

allowing a low voltage current (8-10 volts) to flow

to the P.C. BOARD which in turn activates an

electronic timer.

The timer, which is built-in the P.C. BOARD,

takes over from the evaporator temperature

sensor, the control of the freezing cycle up to its

completion.

NOTE.

The change of the electric potential of

the evaporator sensor with the consequent

activation of the timer (Time mode) is signalled

by the glowing-up of the RED LED located

beside the FREEZING yellow one in the front

of the P.C. BOARD.

ATTENTION. In case, after 15 minutes

from the beginning of the freezing cycle,

the temperature of the evaporator sensor

probe is higher then 0

°

C (32

°

F) (shortage

of refrigerant, inoperative hot gas valve,

etc.) the P.C. BOARD switch OFF

immediately the unit with the

simultaneous blinking of the WARNING

RED LED.

The length of this second portion of the freezing

cycle is pre-fixed and related to the setting of the

first four DIP SWITCH keys.

The DIP SWITCH keys setting is made in

consideration of the type of condenser used.

In Table B are indicated the various lengths of the

second portion of freezing cycle (Time mode) in

relation to the different combinations of the DIP

SWITCH KEYS.

In Table A herebelow are illustrated the DIP

SWITCH key combinations for the three different

factory.

PRINCIPLE OF OPERATION

How it works

In the SCOTSMAN Modular Cubers the water

used to make the ice is kept constantly in

circulation by an electric water pump which primes

it to the self propeller spray bar nozzles from

where it is diverted into the inverted mold cups of

the evaporator (Fig. B).

A small quantity of the sprayed water freezes into

ice; the rest of it cascades by gravity into the

sump assembly below for recirculation.

FREEZING CYCLE (Fig. A)

The hot gas refrigerant discharged out from the

compressor reaches the condenser where, being

cooled down, condenses into liquid. Flowing into

the liquid line it passes through the drier filter,

then it goes all the way through the capillary tube

where, due to the heat exchanging action, it

looses some of its heat content so that its pressure

and temperature are lowered as well.

Next the refrigerant enters into the evaporator

serpentine (which has a larger I.D. then the

capillary) and starts to boil off; this reaction is

emphasized by the heat transferred by the

sprayed water.

The refrigerant then increases in volume and

changes entirely into vapor.

The vapor refrigerant then passes through the

suction accumulator (used to prevent that any

small amount of liquid refrigerant may reach the

compressor) and through the suction line. In both

the accumulator and the suction line it exchanges

heat with the refrigerant flowing into the capillary

tube (warmer), before to be sucked in the

compressor and to be recirculated as hot

compressed refrigerant gas.

The freezing cycle is controlled by the evaporator

temperature sensor (which has its probe in contact

with the evaporator serpentine) that determines

the length of its first portion of the cycle.

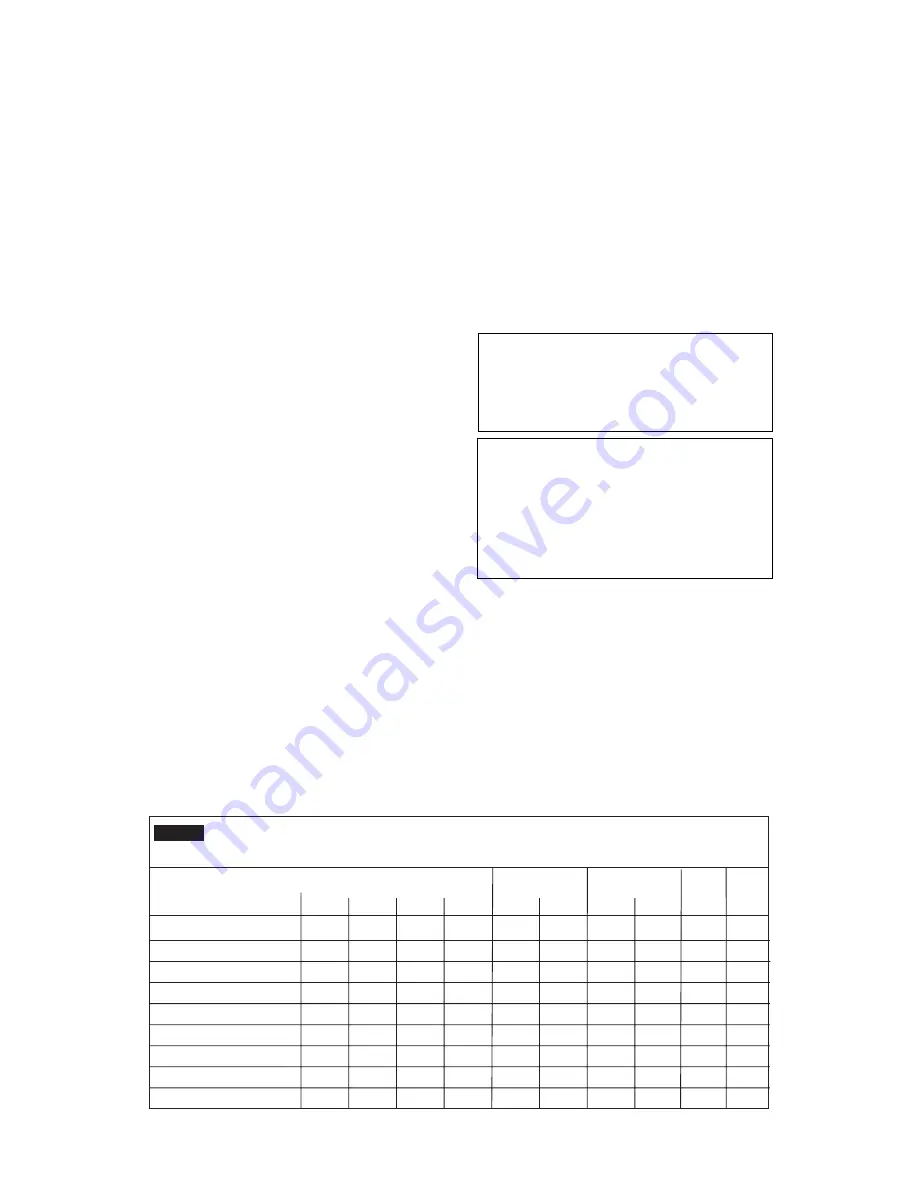

TAB. A

DIP SWITCH FACTORY SETTING COMBINATIONS PER MODEL AND VERSION

DIP SWITCH

1

2

3

4

MCS 15-45 A

MCS 15-45 W

MCM 15 A

MCM 15 W

MCM 45-1210 A

MCM 45-1210 W

MCL 15-45-1210 A

MCL 15-45-1210 W

MCXL 45 W

5

6

7

8

9

10

FREEZING CYCLE

DEFROST CYCLE

DEFR. CYCLE

ADD. TIME

15/30

°

ON

ON

OFF

ON

ON

OFF

ON

ON

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

AIR

WATER

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

Summary of Contents for MC 15

Page 19: ...Page 19 Page 19 ...