Page 18

Page 18

START-UP

START-UP CYCLE

1. Open the water tap/valve and switch ON the

power on the electrical supply line.

2. The models MV 306-426- 456 - 606-806 enter in

the Start Up mode with the PC Board energized as

well as the Green LED of the machine under power

while the model MV 1006 enter in 90 minutes delay

time controlled by a special Start-up Delay PC Board.

The Green LED of machine in operation is

energized too, blinking fast for 40 seconds.

NOTE: The model MV 1006 is equipped

with

a compressor crankcase heater and a Start

up Delay PC Board set up at 90 minutes.

During the first 90 minutes only the

compressor crankcase heater is energized

warning up the compressor.

3.

During the Start Up cycle the components in

operation are:

• Hot gas valve

• Water Drain Valve

• Water Pump

• Harvest assist solenoid (pusher).

FREEZING CYCLE

1.

After the Start Up cycle the machine enters

directly into the Freezing cycle with the following

components energized:

• Water Inlet valve

• Compressor

• Fan motor (in continuous operation for the first

3 minutes).

2.

The LED energized are:

• Machine under power

• Machine in operation (steady)

3.

Water is coming into the water through the

Water Inlet Solenoid Valve till the water reservoir

if filled up to the maximum level controlled by a

Water Level Sensor.

4.

30 seconds later, the Water Pump starts up.

5.

After few minutes (3-5) from the start up of

the freezing cycle, the Water Inlet Solenoid Val-

ve is activated again for few seconds to re-fill the

water reservoir up to the maximum level so to

reduce any possibility of slush ice formation.

6.

In the meantime the condenser sensor starts

to transmit the current to the PC Board keeping

in operation the Fan Motor in ON-OFF mode or

continuously according to the condenser tempe-

rature.

NOTE: Do not remove the evaporator

deflector cover as it will cause the switching

off of the machine at "STORAGE BIN FULL".

7.

The machine remains in the freezing cycle

with the ice that become thicker till the two metal

plates of the Ice Thickness Sensor are covered

by the water cascading through the front surface

of the ice plate.

8.

When the Power is transmitted back to the

PC Board continuously through the metal plates

of the Ice Thickness Sensor for more then 6", the

machine enters in the Pre-Harvest or directly

into the Harvest Cycle mode according to:

• FAN MOTOR IN ON-OFF MODE DURING

THE PREVIOUS FREEZING CYCLE

RISE UP THE CUT IN TEMPERATURE OF

THE CONDENSER SENSOR TO 38

°

C (FAN

MOTOR OFF) AND EXTEND THE LENGTH

OF FREEZING CYCLE BY 30" MORE THEN

GO INTO HARVEST CYCLE

• FAN MOTOR ALWAYS IN OPERATION

DURING THE PREVIOUS FREEZING CYCLE

GO STRAIGHT TO THE HARVEST CYCLE

9.

First freezing time will range between 13

and 17 minutes.

Longer time for temperature above 25

°

C and

shorter time required when temperature are below

25

°

C.

Average complete cycle time is about 15 min.

HARVEST CYCLE

1.

During the harvest cycle the components in

operation are:

• Hot Gas valve

• Harvest assist solenoid (pusher)

• Water Drain/Purge Valve

• Water Pump for the first 6" every cycle and for

all harvest time every 6 cycles

• Compressor

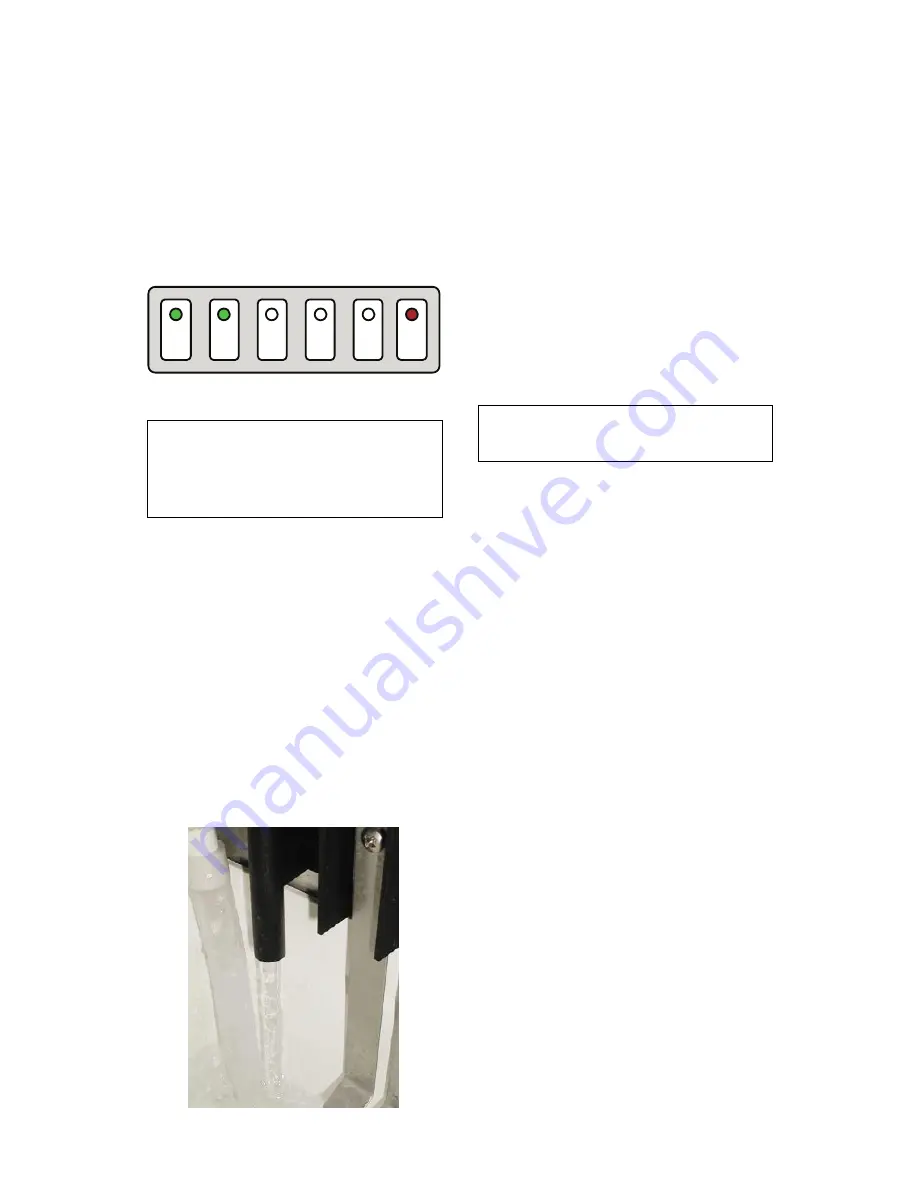

POWER

OPER.

BIN

FULL

ALARM

ALARM

HI

PRESS.

RE-SET