Page 20

Page 20

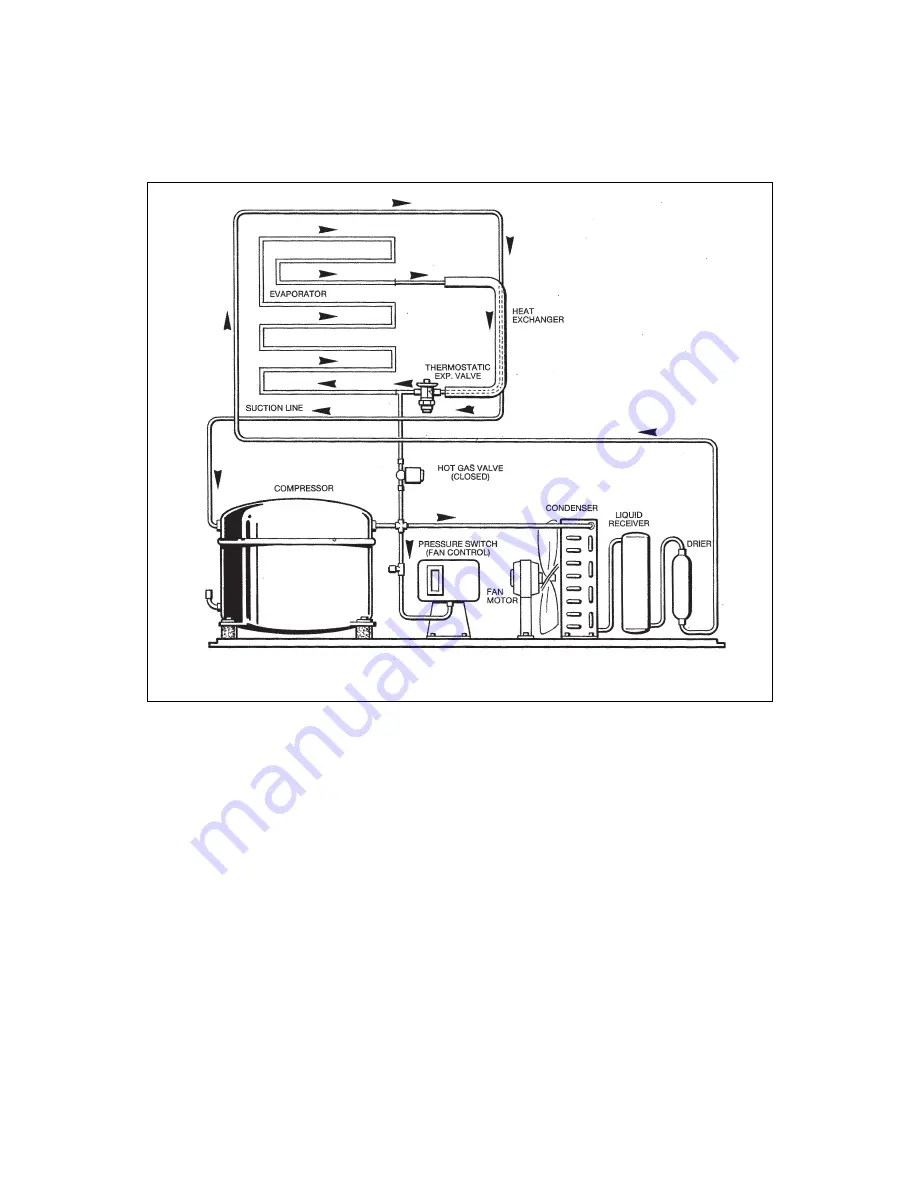

REFRIGERATION DURING FREEZE:

This ice machine employes either air or water as

a condensing media, the refrigeration system for

either one is a follows:

At the hermetic compressor, Refrigerant is

compressed into a high temperature, high

pressure gas.

The gas moves through the discharge line into

the condenser, air or water-cooled. If air-cooled,

the discharge pressure will change with the heat

load and the ambient air temperature.

If water-cooled, the discharge pressure is

controlled by the amount of water flowing through

the condenser - which is determined by the

water regulating valve.

After the gas is cooled in the condenser, giving

up much of its heat, the gas condenses into a

high pressure liquid. This liquid travels through

the liquid line to the metering device, a

thermostatic expansion valve.

The thermostatic expansion valve meters how

much liquid refrigerant is to be allowed into the

evaporator section of the refrigeration system.

This is determined by the temperature of the TXV

sensing bulb, located on the suction line

manifold, at the outlet of the evaporator.

If the bulb senses a warm suction line, more

refrigerant is allowed into the evaporator, (common

at the beginning of the freeze cycle) and when the

temperature begins to fall, less refrigerant is allowed

through.

This is why the suction side gauge pressure will

decline throughout the freeze cycle. At the

evaporator, the liquid refrigerant released from

high pressure, boils off in the low pressure

environment and absorbs heat, thus cooling the

evaporator surface and anything near it, such as

water.

The low pressure refrigerant vapor then is

forced through the heat exchanger where any

excess liquid refrigerant boils-off, allowing only

refrigerant vapor to enter the compressor

suction tube, where it is recompressed into

high pressure, high temperature gas again

and the cycle repeats.

OPERATION

FREEZE CYCLE

REFRIGERATION SYSTEM SCHEMATIC