Page 22

Page 22

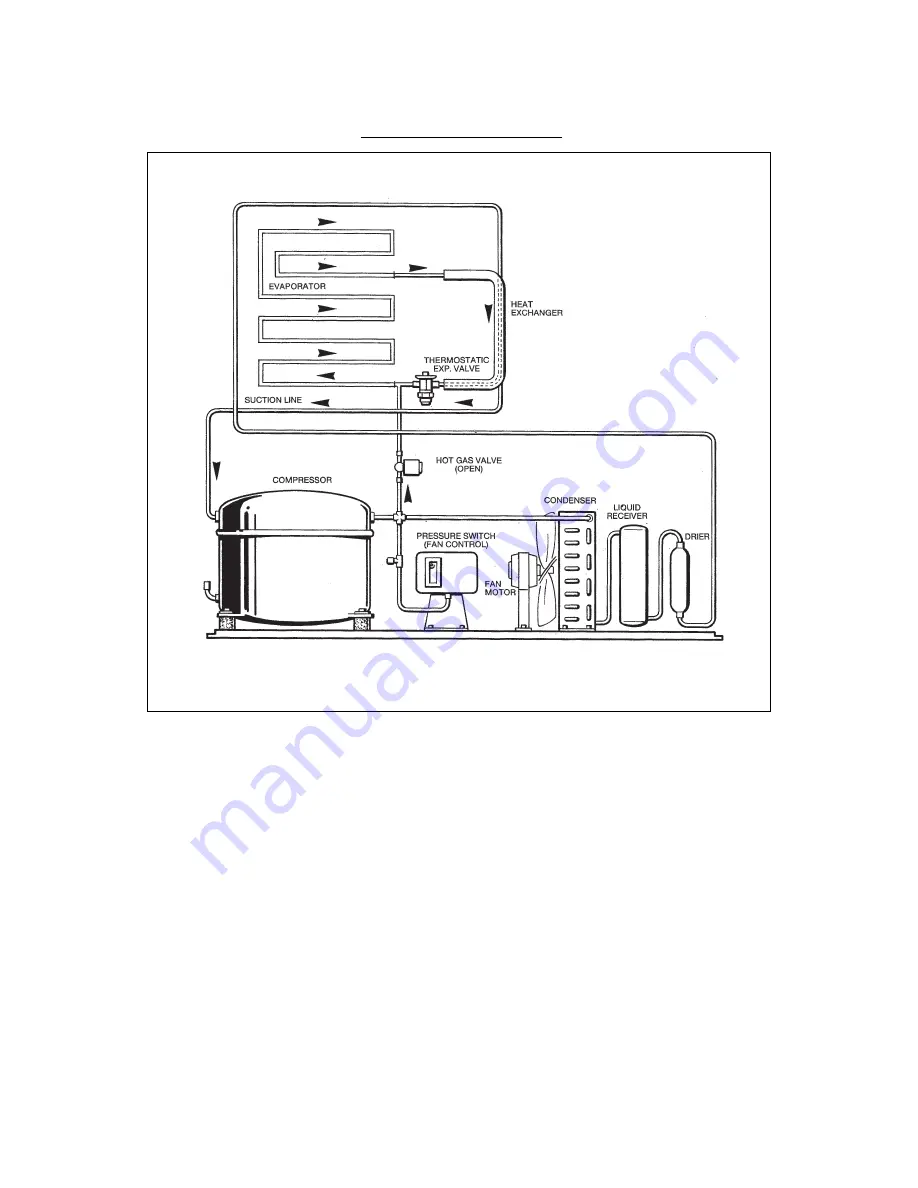

HARVEST (DEFROST) CYCLE

REFRIGERATION SYSTEM SCHEMATIC

REFRIGERATION SYSTEM DURING HARVEST

The refrigeration system performs the harvest of

ice by use of a hot gas bypass valve. When the

time comes to de-ice the evaporators, the hot

gas valve is energized, and the high temperatu-

re, high pressure gas bypasses the condenser,

and is allowed directly into the evaporator. The

high pressure gas is cooled by the cold evaporator

so it condenses into a liquid, giving up its heat as

it does so. This heat warms the evaporator and

the ice frozen onto the evaporator surface melts,

releasing the frozen cubes. Ice then falls into the

storage bin pushed out by means of the harvest

assist solenoid.

The liquid refrigerant goes through the suction

line into the heat exchanger where it boils-off so

that only refrigerant vapor is drawn into the

suction tube of the compressor.

WATER SYSTEM

During the harvest cycle, the electric water

drain valve is energized thereby opening the

drain line.

Most of the water remained in the reservoir at the

end of freezing cycle is pumped-out, to the

waste, through the water solenoid and drain line

during the first part of the defrost cycle eliminating

any possible build-up and accumulation of

minerals concentration and impurities in the water

reservoir.

When the released ice cubes drop into the bin,

they open-up for a while the bottom end of plastic

deflector.

This deflector swinging motion is enough to reset

the contact of the magnetic switch which - via

electronic control board - moves back the unit to

a new freezing cycle.

The harvest cycle lasts about 1

÷

1.5 minutes.

CONTROL SEQUENCE

At the start of the freezing cycle, the contacts of

the magnetic switch mechanically operated by

the actuator plate of the deflector cover are

closed, thereby - via electronic control board -

closing the circuit to the main contactor coil and