Page 16 of 44

P/N 595189-01 Rev A 4/10

regulAr oPerATionAl inSPecTion conTinued...

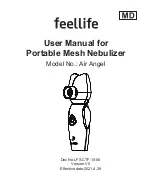

figure 7

COUPLING GASKET

PreSSure

reducing

regulATor

couPling

gASKeT

PRESSURE REDUCER AND AIR PATH INSPECTION

1. Inspect the gauge and ELECTRONIC alarm for damage or modi-

fications that may impair the intrinsic safety. Verify that a fresh

battery is installed in the ELECTRONIC alarm. The ELECTRONIC

alarm requires one 9V battery for operation. See the ELECTRONIC

ALARM BATTERY REPLACEMENT section of this instruction.

2. Inspect the pressure reducer for exterior damage.

3. Inspect the cylinder valve outlet threads and the coupling gasket.

The gasket is located on the nipple coupling that connects the

pressure reducer to the cylinder valve. To expose the threads and

the gasket for inspection, grasp the hand wheel coupling on the

pressure reducer and turn the hand wheel counterclockwise until

the pressure reducer separates from the cylinder valve. Inspect the

cylinder valve outlet for bent or damaged threads. If the gasket is

present and in good condition and the valve outlet is undamaged,

thread the coupling back onto the cylinder valve using hand tight

pressure. See FIGURE 7.

cAuTion

WrencheS ShAll noT be uSed To TighT-

en The hoSe couPling. over TighTen-

ing The hoSe couPling mAy dAmAge

The niPPle SeAl.

WArning

A dAmAged or miSSing couPling gAS-

KeT mAy cAuSe Air leAKAge ThAT mAy

reduce The durATion of uSe Which

could reSulT in circumSTAnceS

ThAT could cAuSe SeriouS inJury or

deATh.