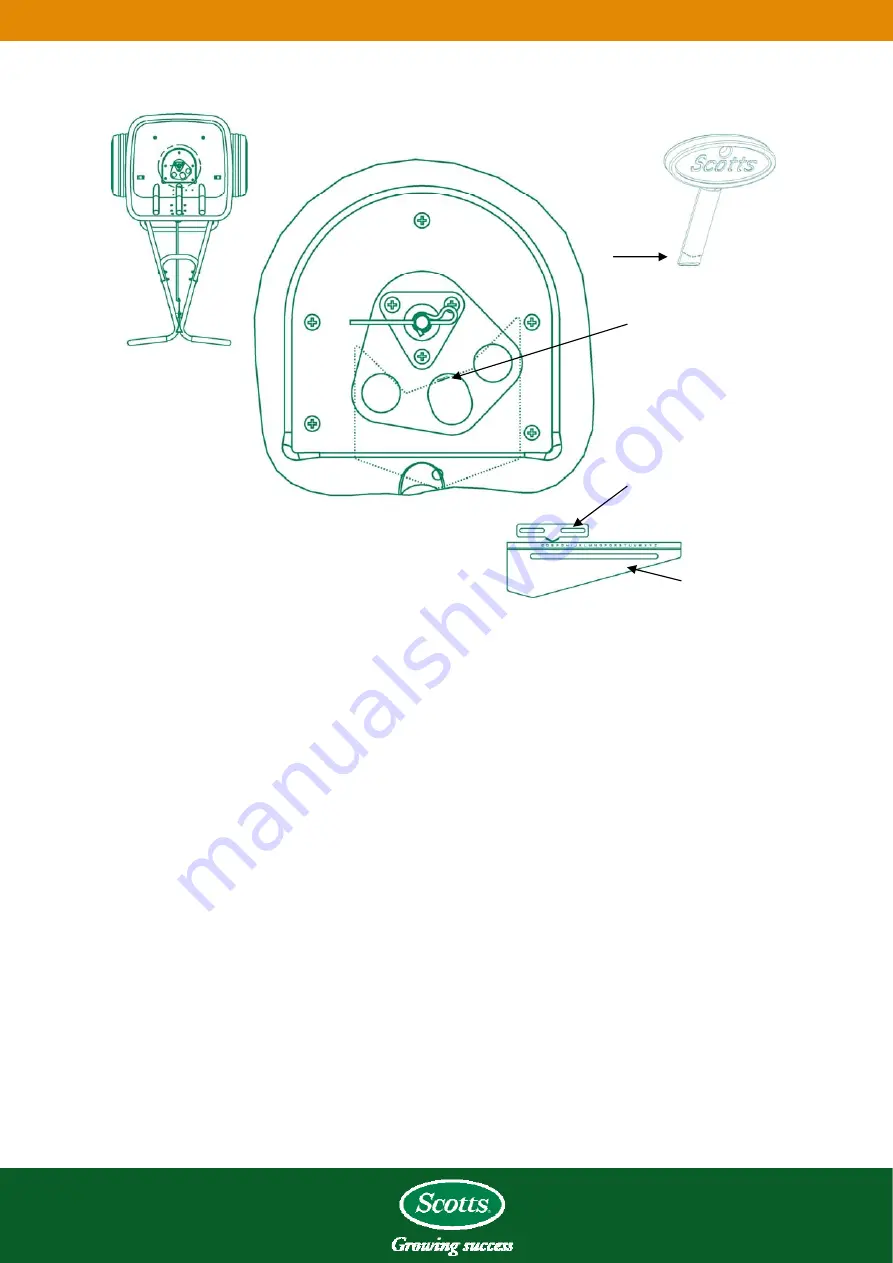

CALIBRATION INSTRUCTIONS

calibration

depth

Calibration Key

Pointer

“E” Position

Rate Control Plate

Your professional spreader has been factory calibrated.

For best results, occasionally check calibration and adjust if necessary.

1. Set the rate control plate to the “E” position.

2. Push the main shutoff lever to the OPEN position.

3. Insert the calibration key vertically into the center port hole, as shown in the accompanying diagram.

4. If the calibration key fits snugly, the spreader is properly calibrated. If not, continue with steps 5-12.

5. Loosen the rate control knob and slide the rate control plate all the way to the left.

6. Insert the calibration key as described in Step #3.

7. Pull the main shutoff lever back to ease the shutoff plate against the calibration key. Use the main shut off lever

to hold the calibration key in place.

8. Slide the rate control plate to the right until it comes in contact with the protruding end of the rate control rod.

9. Tighten the rate control knob.

10. Remove the calibration key and pull the main shut off lever to the closed position.

11. Loosen the nuts securing the rate control pointer and slide the pointer so that it centers on the “E” setting of

the rate control plate.

12. Re-tighten the nuts on the pointer.