Operating Machine - 12

OPERATING MACHINE

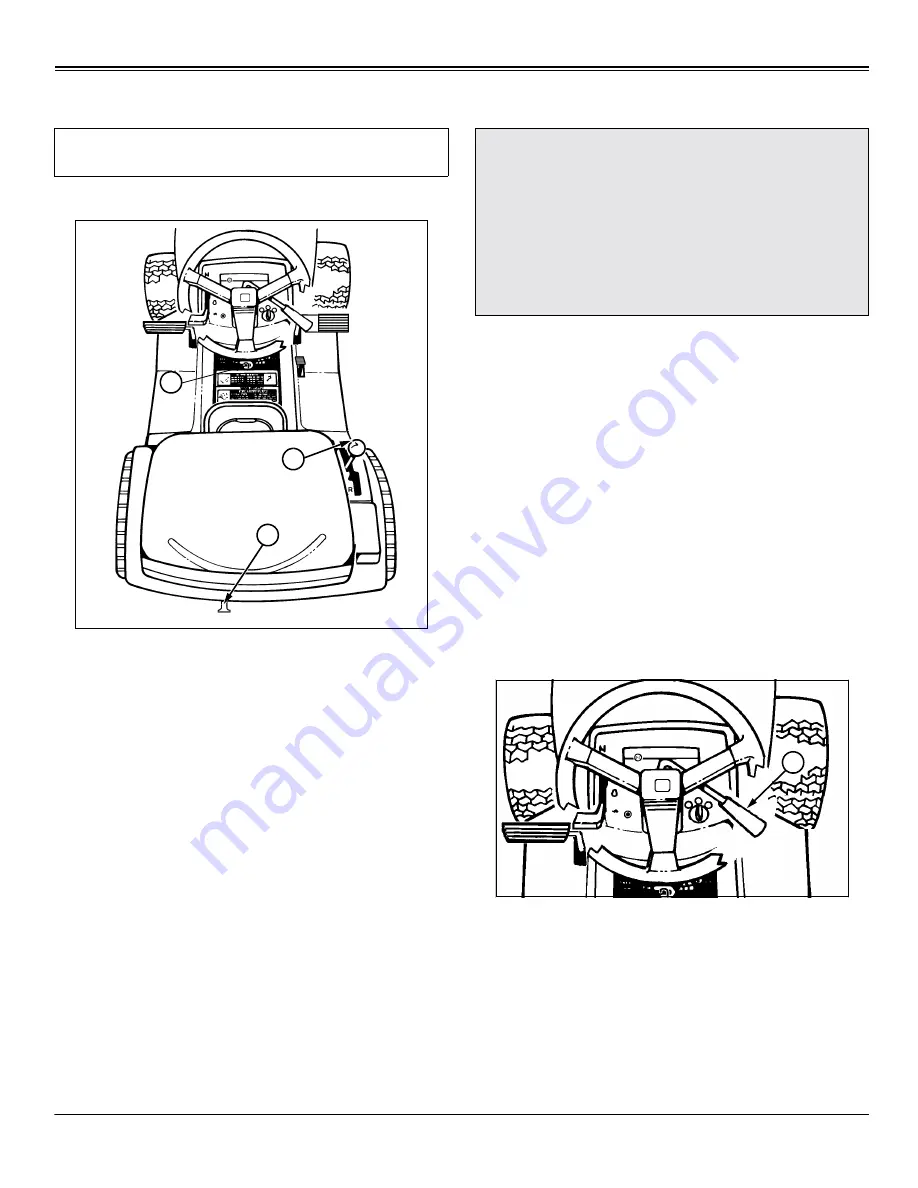

Pushing Machine

To move machine when engine is STOPPED:

•

Unlock the park brake (A).

•

GEAR MODEL: Put transmission shift lever (B) in N

(Neutral).

•

AUTOMATIC MODEL: Pull out on free-wheeling lever

(C).

•

Push machine to desired location.

NOTE: AUTOMATIC MODEL: Push free-wheeling lever

(C) IN before operating tractor.

Daily Operating Checklist

•

Test safety systems.

•

Check tire pressure.

•

Check fuel level.

•

Check engine oil level.

•

Remove grass and debris from machine.

Testing Safety Systems

Use the following checkout procedure to check for normal

operation of machine.

If there is a malfunction during one of these procedures,

DO NOT operate machine. (See your Authorized Service

Center for service.)

Perform these tests in a clear open area. Keep bystanders

away.

NOTE: Your Lawn Tractor is equipped with a

ELECTRONIC SAFETY INTERLOCK. Engine will not

start unless: PTO lever is DISENGAGED. Brake pedal is

depressed OR parking brake is set.

Test 1

1. Operator on seat.

2. Unlock the park brake.

3. Pull PTO lever (A) back to DISENGAGE.

4. Try to start engine.

5. Engine MUST NOT start. If engine starts, there is a

problem with your safety interlock circuit. (See your

Authorized Service Center.)

IMPORTANT: Avoid damage! Avoid transmission

damage, DO NOT tow machine.

B

A

C

c

CAUTION: Avoid injury! Engine exhaust fumes

can cause sickness or death.

If it is necessary to run an engine in an

enclosed area, remove the exhaust fumes from

the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension,

open the doors and get outside air into the

area.

A