Neutralization (Discharge) Times

All data was taken with the fan speed set to high. All time measurements are in seconds.

NOTE: Discharge times in seconds are representative only and are not a guarantee. Discharge times are actual

measurements recorded in a factory ambient environment.

Per ANSI/ESD S20.20

,

the test method for Product Qualification test is ANSI/ESD STM3.1, and for Compl

i

ance

Verification is ESD TR53 which advises

"

Measurements should be made at the location where ESD sensitive items

are to be

i

onized

."

A larger area may require additional ionizers. Per S20.20 the required limit for ionizer discharge

time is user defined. Use Table to determine the number of ionizers to achieve ionization of area to be neutralized

to meet your company's ESD control plan specified discharge times.

The comparative efficiency of bench top

i

onizers is determined by a standard test published by the ESD

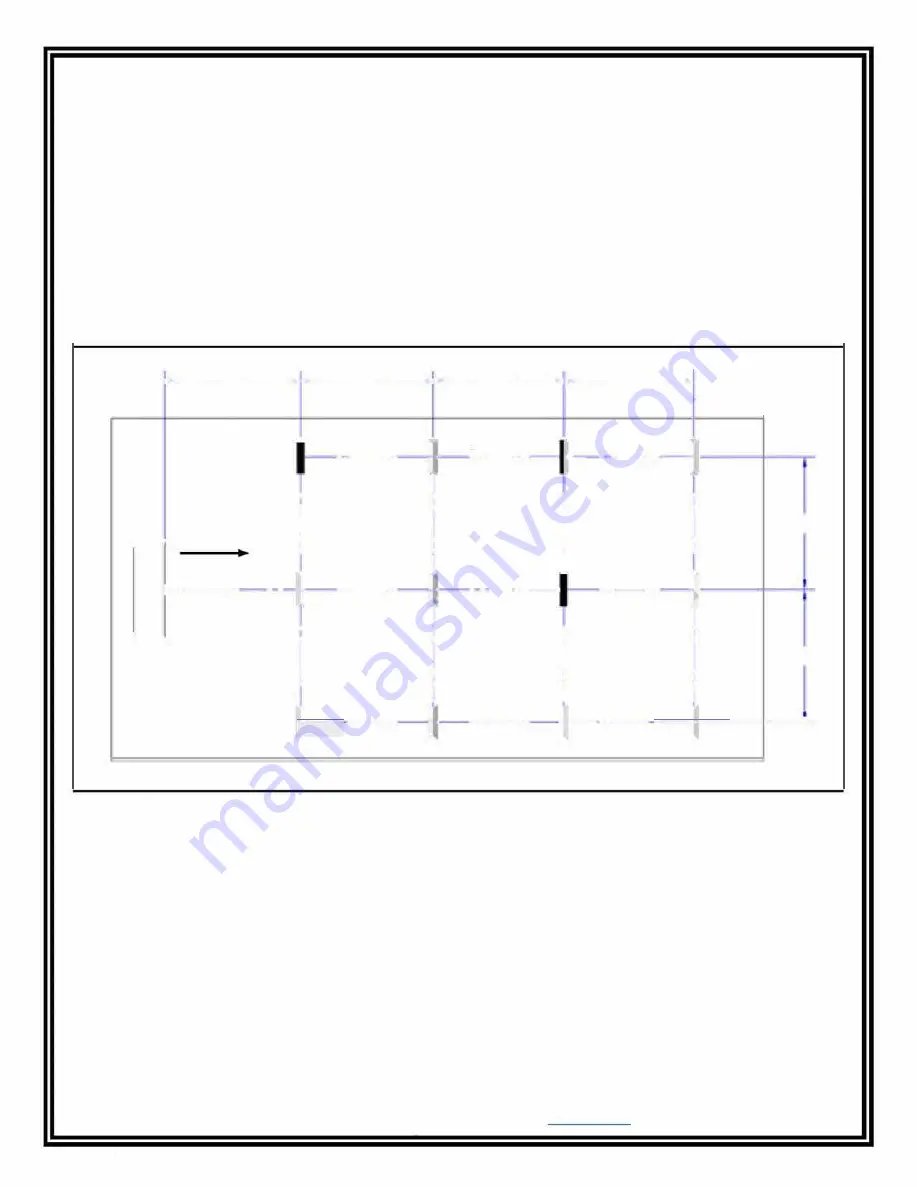

Association: ANSI/ESD STM3.1. Typical positive and negative decay times (±1000V to ±100V) measured using this

standard are shown in Figure 3. The performance of the ionizer was measured with the unit positioned as shown,

with the fan speed on high and without a filter.

-

--

12

"

--

-

--

--

12

"

--

--

--

12

"

---

-

--

12"

--

-

TP1 -•174:'

__

T

7

·

-

-

�

l

-

t:!}

--

T

!2!

1 +

30.5

Charged Plate -159.6

-34.3

-22.9

-35.7

-

Air Flow

-

----

-

963E Benchtop

Air Ionizer

I

I

I

l

I

I

I

I

I

I

I

I

TP2

I

+1.1

__ •

TPS '+3.2

TP8

+6.6

. __

TP11

I

+

1

0.6

---

-1.2

-3.5

-7.5

-11.1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

12"

12"

TP3

I

+53.2

___

TP6

I

+8.5

____

TP9 �

- __

TP12

1

_

+

_

1

_

1

_

.o

____._

-55.3

-10.0

(T4

-12.7

Figure 3. Neutralization (Discharge) Times

TB-9007

Page 3 of 4

@ 2020 DESCO NDUSTRIES, NC

.

Employee Owned