Chiller wired controller

Unit number setting

Press the FUNCTIONS key 4 times to enter the unit number setting. Press

▲

or

▼

to adjust the unit

number. Press OK key when finished or wait for 7 seconds to confirm. During the setting process,

pressing the CANCEL key to exit without saving. The setting value is 0-19.

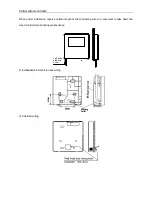

Forced open water pump

Press the FUNCTIONS key 5 times to force open the water pump. The water pump icon will flash.

Press OK key to confirm. During the setting process pressing the CANCEL key to return to the main

interface, and log off the forced water pump mode.

Notes:

a. Forcing water pump function is only limited to stand-by mode, others modes not response.

b. Under forcing water pump function, other settings will not responsible, except stopping

c. When communication disconnects, it will show E2 error in 2 minutes, the wired controller will

automatically cancel the forcing water pump function; while connected, the wired controller keeps