Operation & Maintenance Manual

──

LG968 /969Wheel Loader

97

2.5 Maintenance Tools

Refer to the production containerization list for details of maintenance tools.

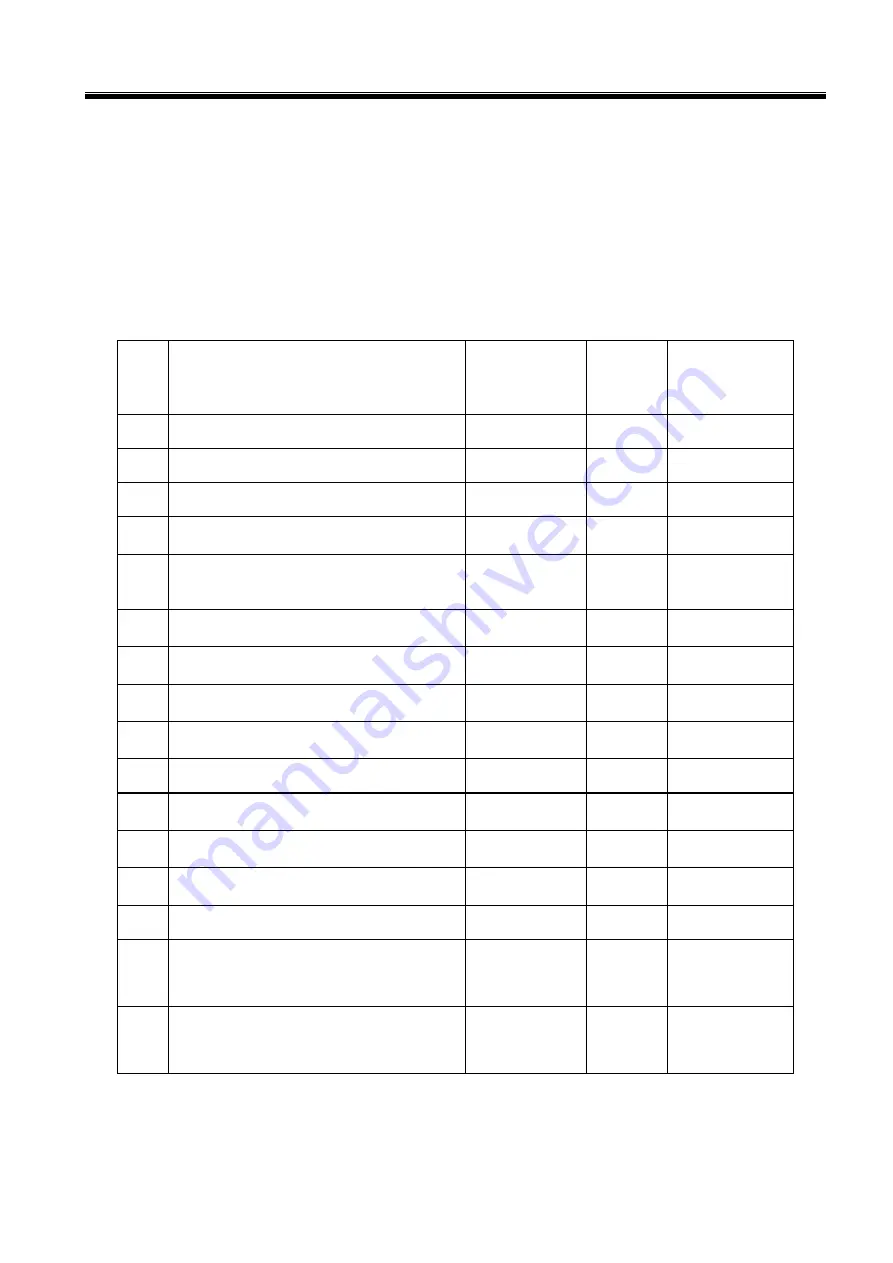

2.6 Tightening Torque of Threads

Be sure to carry out the maintenance following the table lists which is the standard tightening torque

of threads in the main components, except for specified conditions.

No.

Position

Thread size

Material

or

character

calss

Torque(N.m)

1

Assembling bolts of transmission base

M18×40 8.8

240

~

280

2

Middle cover bolts of transmission base

M14×35 10.9

125

~

165

3

Assembling bolts of hub and brake disc

M20×1.5×50 8.8 280

~

380

4

Assembling bolts of left and right

differential carriers in the main transmission

M16×1.5×150 40Cr 280

~

330

5

Assembling bolts of driven spiral gear and

right differential carrier in the main

transmission

M16×1.5×55 40Cr 280

~

330

6

Assembling bolts of bearing bracket and

carrier in the main transmission

M22×100 40Cr

500

~

600

7

Lock nuts of input flange in the main

transmission

M33×1.5 8

320

~

400

8

Assembling nuts of planetary gear carrier

and hub

M20×1.5 40Cr

500

~

600

9

Assembling nuts between main

transmission carrier and axle housing

M16×1. 5×45

8.8

193

~

257

10 Rim

nuts

M20×1.5 35

480

~

580

11

Assembling bolts between brake pliers and

carrier

M20×1.5×56 40Cr 376

~

502

12

Assembling bolts between driving axle and

frame

M30×2×175

45

530~670

13

Assembling bolts at the middle of driving

shaft

M14×1.5×55

8.8

125~165

14

Assembling of mobile oil box and frame

M16×35

8.8

185~265

15

Assembling bolts between fuel tank and

frame

M24×2×130

M24×2×80

8.8

320~480

16

Assembling bolts between teeth and bucket

M20×85

M20×62

45

376~502