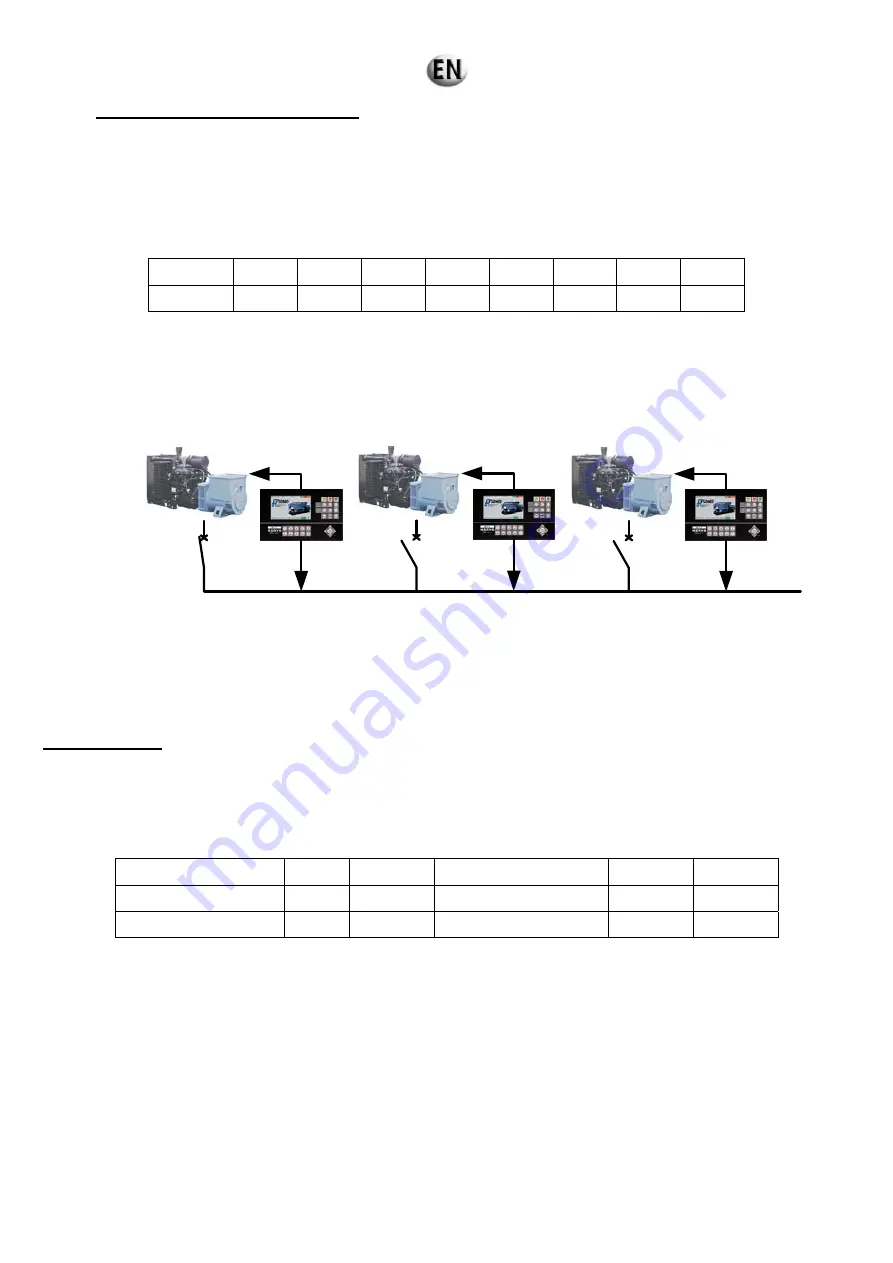

Principle of coupling in normal operation

Coupling in normal operation enables all the generating sets to be coupled (in voltage and frequency) to a busbar supplied by

a generating set designed as master at the output.

A number (1 to 15) is assigned to each Kerys. This number serves solely to establish the IP address of each Kerys for

communication by Ethernet and loading the programs.

A second number (from 1 to 15) is also assigned to each Kerys and defines the priority.

Example: let us assume a plant of 8 generating sets

Gen

set 1 2 3 4 5 6 7 8

Priority 08 07 06 05 04 03 02 01

The numbers on the first line enable the IP address of each Kerys to be allocated. The numbers on the second line define the

priority.

Therefore Kerys no. 8 with priority 01 is considered to be the master generating set and closes its flow first. The other

generating sets then synchronise one by one to the central busbar, transmitting the information on voltage, frequency and

phase difference to this busbar (see sketch).

CB1

GS1

U1

CB2

GS2

U2

CB3

GS3

U3

Busbar U

Example for 3 GSs:

•

DJ1 (Circuit breaker 1) is closed, the voltage is present on the busbar.

•

Kerys 2 analyses the differences between U2 and U of the busbar before coupling.

•

Kerys 3 analyses the differences between U3 and U of the busbar before coupling.

Each Kerys, independently of its neighbour, will close its discharge on the central busbar.

Wattmetric control

The wattmetric control is used when two generating sets are coupled. It provides optimum management of the number of generating

sets operating by constantly analysing the power required by the user.

Let us take the example of a power plant of 4 x 600 kW generating sets.

The threshold setting screen (1-7-3-3) supplies the following data:

Threshold 1 GS => 2 GS

75%

450 kW

Threshold 2 GS => 1 GS

30 %

360 kW

Threshold 2 GS => 3 GS

75%

900 kW

Threshold 3 GS => 2 GS

30 %

540 kW

Threshold 3 GS => 4 GS

75%

1350 kW

Threshold 4 GS => 3 GS

30 %

720 kW

The maximum available power is 600 x 4 = 2400 kW. Assuming that a single generating set is operating, we will have the following

sequence in the case of linear progression of the load.

When the power required by the application reaches 75% of the power of the generating set in operation (GS at priority 01), i.e.

450 kW, the second GS (at priority 02) is started and is synchronised with GS 1. Its flow is then closed.

72/297

Summary of Contents for R570U

Page 1: ...User and maintenance manual for generating sets R570U 33504081501NE_1_1 ...

Page 15: ...Alternator Cabinet Figure 1 3 Examples of identification plates 13 297 ...

Page 18: ...Sockets voltage 208 120V 16 297 ...

Page 125: ...9 Appendix 9 1 Appendix A Engine user and maintenance manual 123 297 ...

Page 126: ...124 297 ...

Page 128: ...126 297 ...

Page 129: ...OPERATOR S MANUAL Generating set and industrial engines 16 liter EMS 2 127 297 ...

Page 159: ...157 297 ...

Page 218: ...216 297 ...

Page 220: ...218 297 ...

Page 222: ...7748681 English 12 2011 220 297 ...

Page 223: ...9 2 Appendix B Alternator user and maintenance manual 221 297 ...

Page 224: ...222 297 ...

Page 226: ...224 297 ...

Page 250: ...www leroy somer com 248 297 ...

Page 261: ...Installation and maintenance R250 A V R 4067 en 2009 05 b LEROY SOMER 11 259 297 ...

Page 281: ...2012 03 e LEROY SOMER 19 Installation and maintenance R 450 AVRs 4531 en 279 297 ...

Page 282: ...www leroy somer com 280 297 ...