Manual revision 041

Appendix I: Functional Description

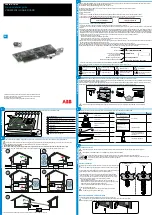

SBE 37-SM RS-232

72

Appendix I: Functional Description

Sensors

The MicroCAT embodies the same sensor elements (3-electrode, 2-terminal,

borosilicate glass cell, and pressure-protected thermistor) previously

employed in our modular SBE 3 and SBE 4 sensors and in the Seacat and

Seacat

plus

family.

The MicroCAT’s optional strain-gauge pressure sensor is available in the

following pressure ranges: 20, 100, 350, 600, 1000, 2000, 3500, and

7000 meters. Compensation of the temperature influence on pressure offset

and scale is performed by the MicroCAT’s CPU.

Sensor Interface

Temperature is acquired by applying an AC excitation to a hermetically sealed

VISHAY reference resistor and an ultra-stable aged thermistor with a drift rate

of less than 0.002°C per year. A 24-bit A/D converter digitizes the outputs of

the reference resistor and thermistor (and optional pressure sensor).

AC excitation and ratiometric comparison using a common processing channel

avoids errors caused by parasitic thermocouples, offset voltages, leakage

currents, and reference errors.

Conductivity is acquired using an ultra-precision Wien Bridge oscillator to

generate a frequency output in response to changes in conductivity.

Real-Time Clock

To minimize power and improve clock accuracy, a temperature-compensated

crystal oscillator (TCXO) is used as the real-time-clock frequency source.

The TCXO is accurate to ± 1 minute per year (0 ºC to 40 ºC).

Note:

Pressure ranges are expressed

in meters of deployment

depth capability.