LO

N

G

T

ERM

STOR

A

GE

If you do not intend to use your watermaker again within the next 7 days (5 days in hotter climates), the

watermaker should be pickled. Pickling introduces chemicals into the system to prevent the growth of

microorganisms that will damage the membrane.

The pickling process will preserve the membrane for up to 6 months. If the watermaker will be inactive

for longer durations, the pickling process must be repeated every 6 months.

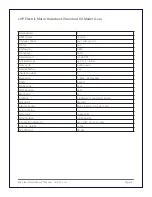

❶

Using the 5 gallons of product water made during start-up*, add 5 tablespoons of sodium

metabisul

fi

te to the bucket and mix until dissolved. (Sodium metabisul

fi

te is readily available

wherever you

fi

nd beer brewing supplies.)

❷

Put the hose labeled “Flush water intake” into the bucket and turn the Sea Water valve to the “Flush

water intake” position (valve should be horizontal).

❸

Turn o

ff

the Seawater Lift Pump using the switch on the panel labeled “Seawater Lift Pump.”

❹

The pickling solution will

fl

ow from the bucket back through the system. When the bucket is empty,

let the watermaker run for an additional 5 seconds before shutting down.

❺

Turn o

ff

the High Pressure Pump using the switch on the panel labeled “H.P. Clutch.”

►►►

Do not let the pump run dry for more than a few seconds; this will damage your system.

If the watermaker may be exposed to freezing temperatures, antifreeze must be introduced

into the system. Please follow “Cold Weather Storage” procedure on the next page.

Sea Clear Watermakers™ Manual - Version 1.1-G

Page 14

* If for any reason you are unable to operate the watermaker (e.g., during haul out) and you

do not have 5 gallons of product water available, you may use clean tap water instead.

However, the tap water must be run through a charcoal

fi

lter

fi

rst to eliminate all chlorine,

as this will damage your membrane.