Section 05 FUEL SYSTEM

Subsection 01 (FUEL TANK AND FUEL PUMP)

-

+

F18F0VA

BAT

A

a. If battery voltage is read, check continuity of

circuit B-29 going towards ECM. If it is good,

try a new ECM.

b. If battery voltage is not read, check continuity

of circuit 1-26 going towards MPEM. If it is

good, try a new MPEM.

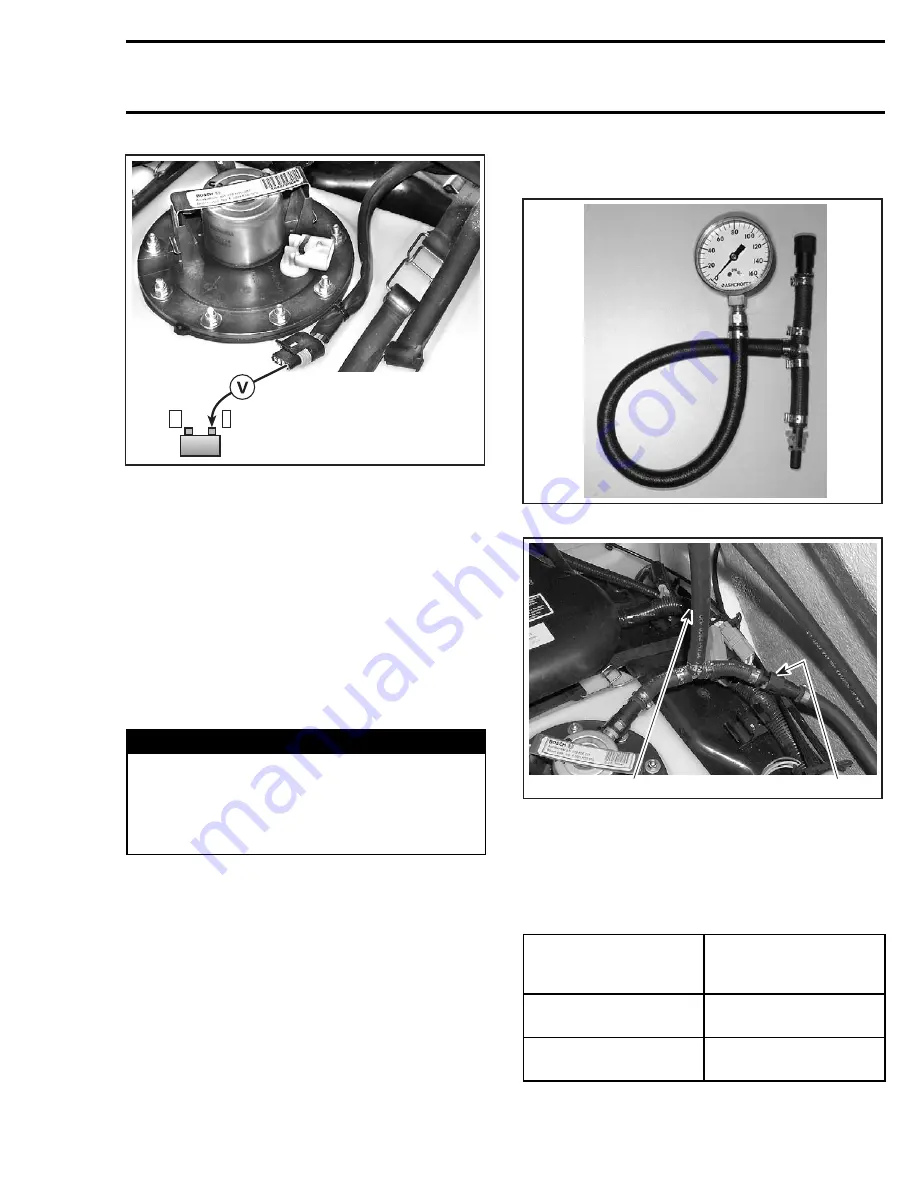

Fuel Pump Pressure Test

Before proceeding to the pressure test ensure the

battery is fully charged. Battery voltage must be

over 12 volts.

Release the fuel pressure in the system using

B.U.D.S. Look in the

Activation

tab.

WARNING

The fuel hose may be under pressure. Cov-

er the fuel line connection with an absorbent

shop rag. Slowly disconnect the fuel hose

to release the pressure. Wipe off any fuel

spillage inside bilge.

The pressure test will show the available pressure

at the fuel pump outlet. It validates the pressure

regulator, the fuel pump and leaks in the system.

Remove glove box to have access to fuel pump.

Refer to HULL/BODY section.

Remove air vent tube from front storage area.

Ensure there is no leak from hoses and fittings.

Repair any leak.

Ensure there is enough gas in fuel tank.

Disconnect outlet hose from fuel pump.

Install fuel pressure gauge (P/N 529 035 591) be-

tween disconnected hose (inline installation).

F02B0BA

FUEL PRESSURE GAUGE

1

F18R08A

2

1. Hose disconnected from fuel pump

2. In-line installation of fuel pressure gauge

Install safety lanyard and observe fuel pressure.

Do not crank engine.

Repeat twice. Release

pressure using B.U.D.S. between tests so that the

gauge is “reset” to zero (0).

MODELS

FUEL PRESSURE

(when installing safety

lanyard)

4-TEC naturally

aspirated/supercharged

290-310 kPa (42-45 PSI)

4-TEC supercharged

intercooled

386-414 kPa (56-60 PSI)

smr2005-014

141

www.SeaDooManuals.net