Section 07 PROPULSION

Subsection 02 (DRIVE SYSTEM)

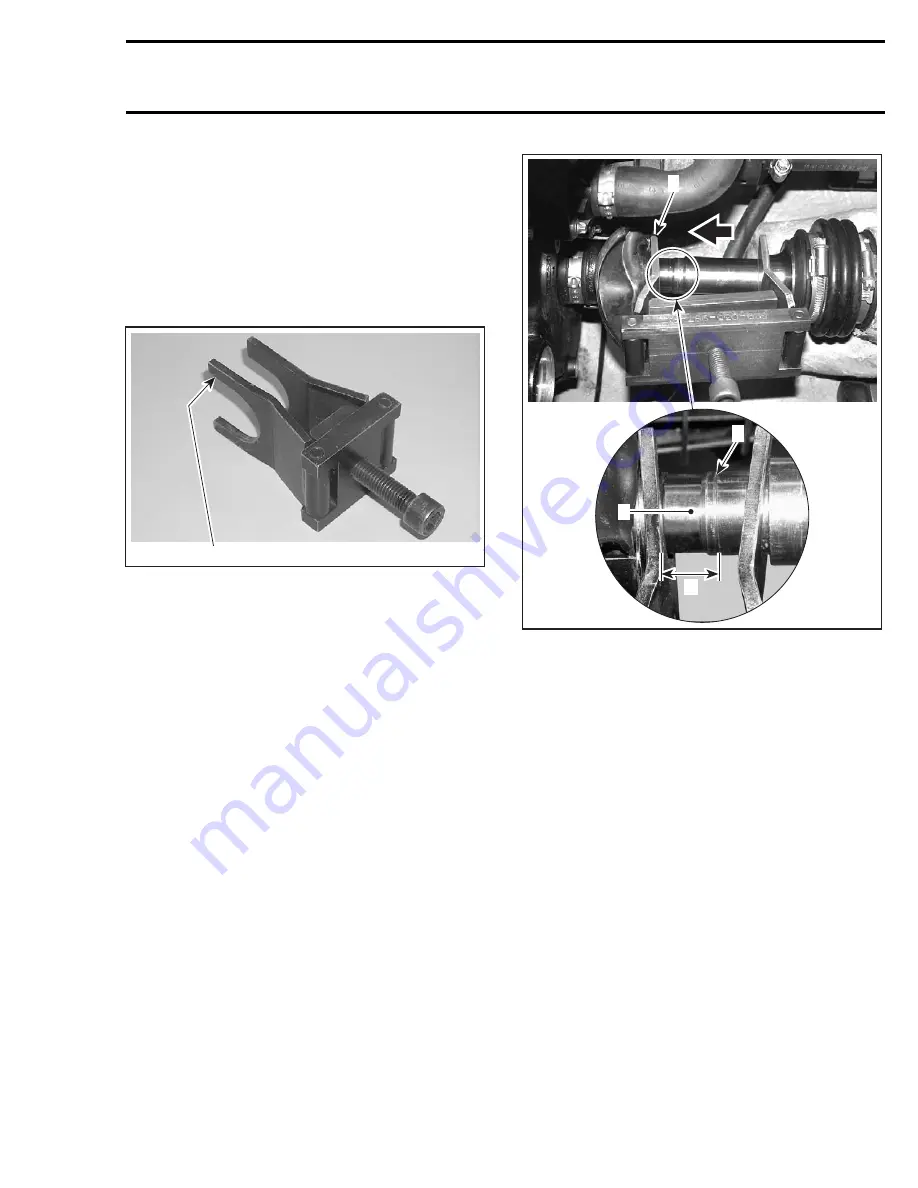

Turn screw clockwise so that the tool pushes the

floating ring

no. 1

rearwards to expose the circlip

no. 2

. Do not remove circlip at this time.

NOTE:

This step is done to ensure floating ring is

free and not stuck on the drive shaft

no. 3

.

Remove drive shaft/floating ring tool and drive

shaft holder.

Reinstall drive shaft/floating ring tool as shown.

1

F18I0OA

TYPICAL

1. Largest opening on PTO seal side

F18I0TA

1

2

3

A

TYPICAL

1. Largest opening here

2. Telltale groove

3. Lubricate O-rings contact area

A. 18 mm (.71 in)

Turn screw clockwise so that the tool pushes the

PTO seal forward and the drive shaft to the rear to

expose the O-rings contact area. Continue to pull

drive shaft out until there is a distance of 18 mm

(.71 in) between the telltale groove and the tool

edge. Lubricate O-rings contact area with BOM-

BARDIER LUBE (P/N 293 600 016).

NOTE:

This is necessary to ease drive shaft re-

moval later in this procedure.

Remove drive shaft/floating ring tool.

Reinstall drive shaft holder tool.

smr2005-020

207

www.SeaDooManuals.net