Section 07 PROPULSION

Subsection 03 (REVERSE SYSTEM)

– bracket

no. 6

2

F16J0FA

1

TYPICAL

1. Bracket

2. Reverse cable

– bolts

no. 7

.

Withdraw reverse cable support

no. 8

.

Handle Housing

Remove:

– shift lever

– interior lever

– reverse cable support

– bolts

no. 9

.

Then, remove handle housing

no. 10

.

INSPECTION

Visually inspect parts for wear or cracks on friction

parts. Replace all defective parts.

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

When installing handle housing, apply Loctite 243

(blue) (P/N 293 800 060) on threads of screws.

Insert interior lever cursor into reverse cable sup-

port slider and make sure that the cursor slides

freely in the slider.

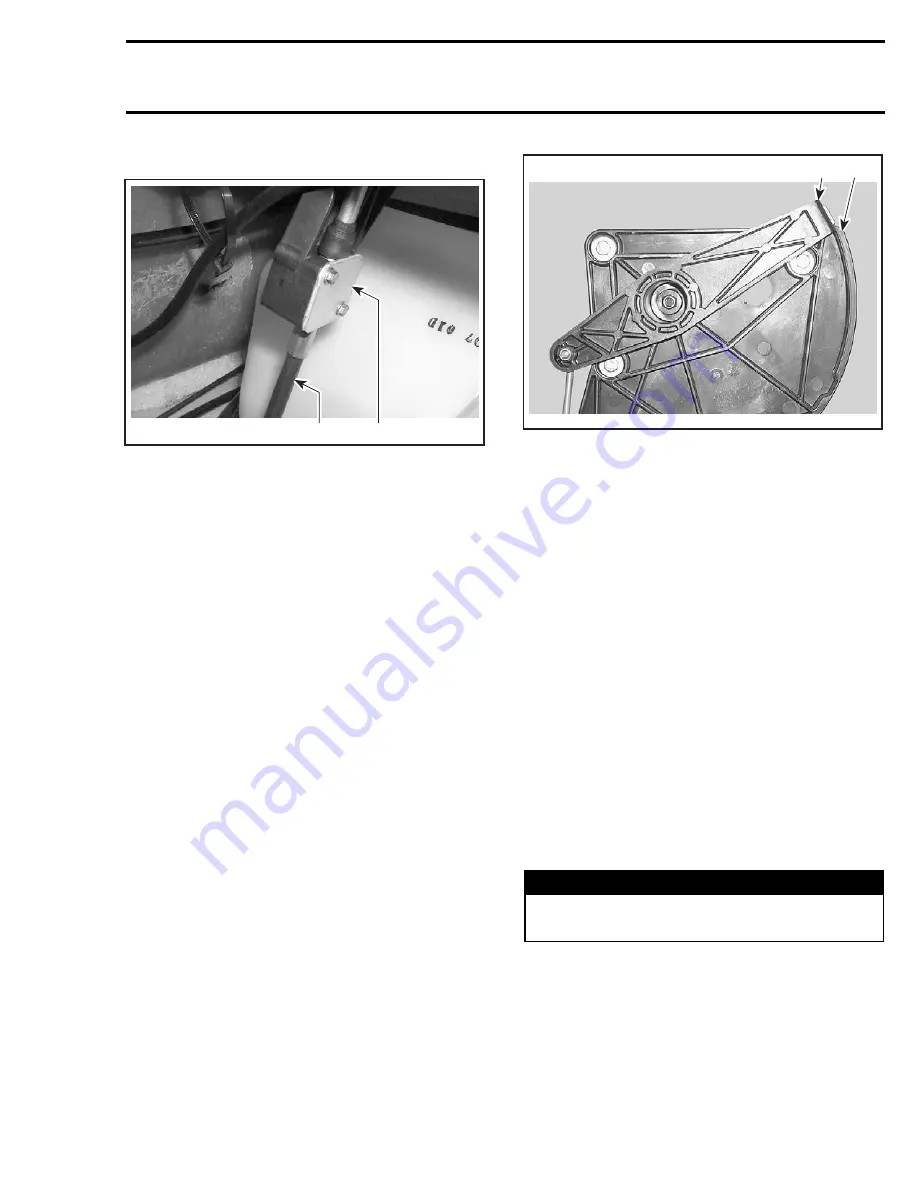

1

F18J1LA

2

TYPICAL

1. Interior lever cursor

2. Reverse cable support slider

Interior Lever

Apply synthetic grease (P/N 293 550 010) on the

interior lever pivot and in the reverse cable support

hole.

Install the interior lever in a rotating movement.

Engage properly the interior lever tabs in the shift

lever slots.

Make sure the shift lever action is smooth and

precise. Forward and reverse positions should be

easy to select with a decent position between

each.

Reverse Gate

Refer to JET PUMP section.

Reinstall removed parts.

ADJUSTMENT

Put shift lever in forward position.

WARNING

When adjusting reverse cable, make sure

lever is well engaged into the spring slot.

Place reverse gate in the up position.

Turn the joint at the end of reverse cable and align

its hole with hole in pivot arm.

Secure with bolt, washers, spacer and elastic stop

nut. Torque to 7 N•m (62 lbf•

in

).

smr2005-021

219

www.SeaDooManuals.net