Section 03

ENGINE

Sub-Section 05

(TOP END)

03-05-8

Clean piston ring grooves with a groove cleaner

tool, or a piece of broken ring.

INSPECTION

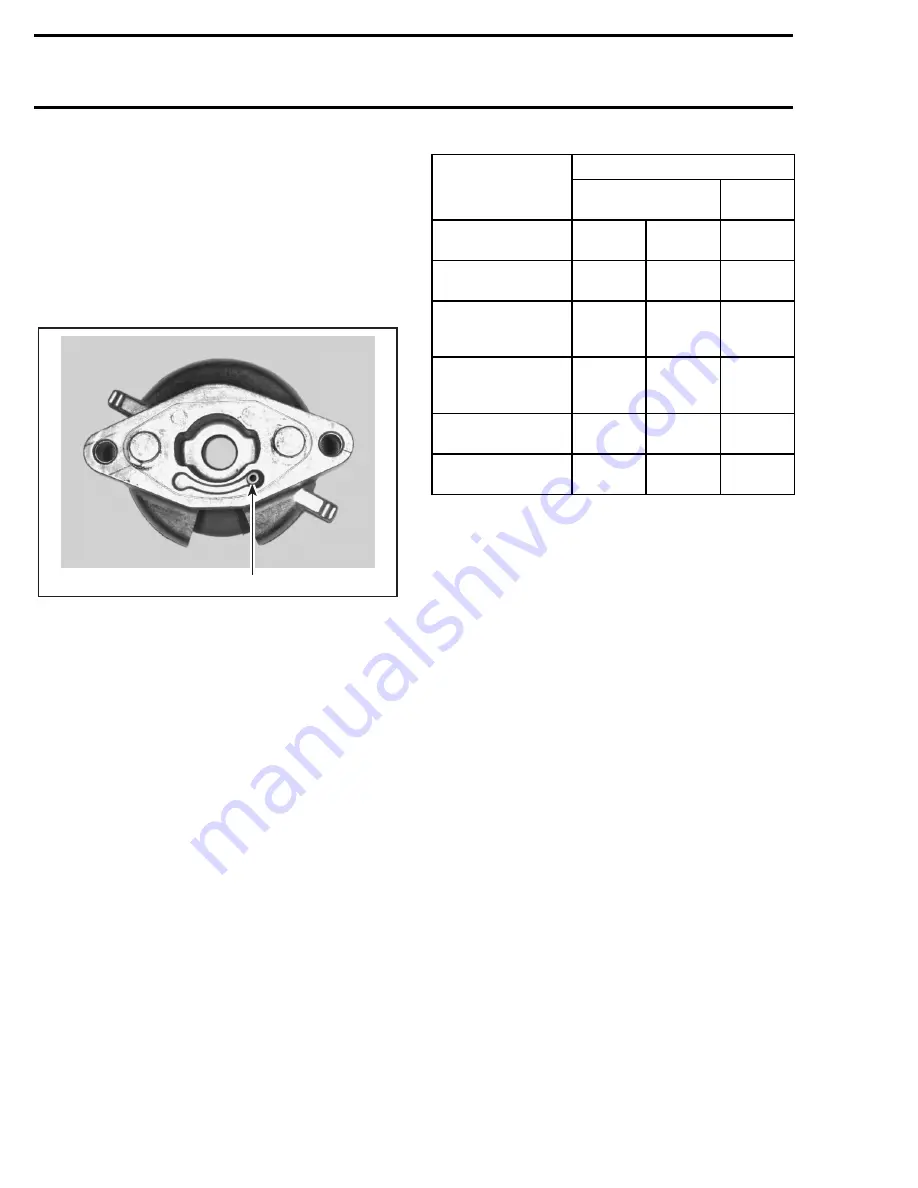

787 Engine

Check RAVE valve bellow

no. 23

for cracks.

Check if passages of valve housing

no. 27

and cyl-

inder

no. 9

are not obstructed.

1. Passage of valve housing

All Engines

Visually inspect all parts for corrosion damage.

Inspect piston for damage. Light scratches can be

sanded with a fine sand paper.

NOTE:

When repairing a seized engine, connect-

ing rods should be checked for straightness and

crankshaft for deflection/misalignment. Refer to

ENGINE 03-06 for procedures.

Inspect plane surfaces for warpage. Small defor-

mation can be corrected by grinding surface with

a fine sand paper. Install sand paper on a surface

plate and rub part against oiled sand paper.

The inspection of engine top end should include

the following measurements.

N.A.: Not Applicable

NOTE:

Replacement cylinder sleeves are avail-

able if necessary. Also, oversize pistons of 0.25

mm (.010 in) are available for all engines and over-

size pistons of 0.5 mm (.020 in) are available for

717 engines.

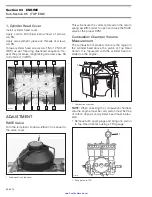

Cylinder Taper

Using a cylinder bore gauge, measure cylinder diam-

eter at 16 mm (5/8 in) from top of cylinder just below

auxiliary transfer port, facing exhaust port. If the dif-

ference between readings exceed specification, cyl-

inder should be rebored and honed or replaced.

F01D8JA

1

ENGINE

MEASUREMENT

TOLERANCES

NEW PARTS

(min.) (max.)

WEAR

LIMIT

Cylinder Taper

N.A.

0.05 mm

(.002 in)

0.1 mm

(.004 in)

Cylinder Out

of Round

N.A.

0.008 mm

(.0003 in)

0.08 mm

(.003 in)

Piston/Cylinder Wall

Clearance for

717 Engines

0.06 mm

(.0024 in)

0.11 mm

(.004 in)

0.20 mm

(.008 in)

Piston/Cylinder Wall

Clearance for the

787 Engine

0.10 mm

(.004 in)

0.12 mm

(.005 in)

0.20 mm

(.008 in)

Ring/Piston Groove

Clearance

0.03 mm

(.001 in)

0.07 mm

(.003 in)

0.20 mm

(.008 in)

Ring End Gap

0.25 mm

(.010 in)

0.40 mm

(.016 in)

1.0 mm

(.039 in)

www.SeaDooManuals.net

Summary of Contents for 1997 GSI

Page 1: ...www SeaDooManuals net ...

Page 2: ...0 0 SHOP MANUAL 0 219 100 048 www SeaDooManuals net ...

Page 343: ...www SeaDooManuals net ...

Page 344: ...www SeaDooManuals net ...

Page 345: ...www SeaDooManuals net ...

Page 346: ...www SeaDooManuals net ...

Page 347: ...www SeaDooManuals net ...

Page 348: ...www SeaDooManuals net ...

Page 349: ...www SeaDooManuals net ...

Page 350: ...www SeaDooManuals net ...

Page 351: ...www SeaDooManuals net ...

Page 352: ...www SeaDooManuals net ...

Page 353: ...www SeaDooManuals net ...

Page 354: ...www SeaDooManuals net ...

Page 355: ...www SeaDooManuals net ...

Page 356: ...www SeaDooManuals net ...

Page 357: ...www SeaDooManuals net ...

Page 358: ...www SeaDooManuals net ...

Page 359: ...www SeaDooManuals net ...

Page 360: ...www SeaDooManuals net ...

Page 361: ...www SeaDooManuals net ...

Page 362: ...www SeaDooManuals net ...

Page 363: ...www SeaDooManuals net ...

Page 364: ...www SeaDooManuals net ...

Page 365: ...www SeaDooManuals net ...

Page 366: ...www SeaDooManuals net ...

Page 367: ...www SeaDooManuals net ...

Page 368: ...www SeaDooManuals net ...

Page 369: ...www SeaDooManuals net ...

Page 370: ...www SeaDooManuals net ...

Page 371: ...www SeaDooManuals net ...

Page 372: ...www SeaDooManuals net ...