Section 05

COOLING SYSTEM

Sub-Section 02

(CIRCUIT)

05-02-2

All Models

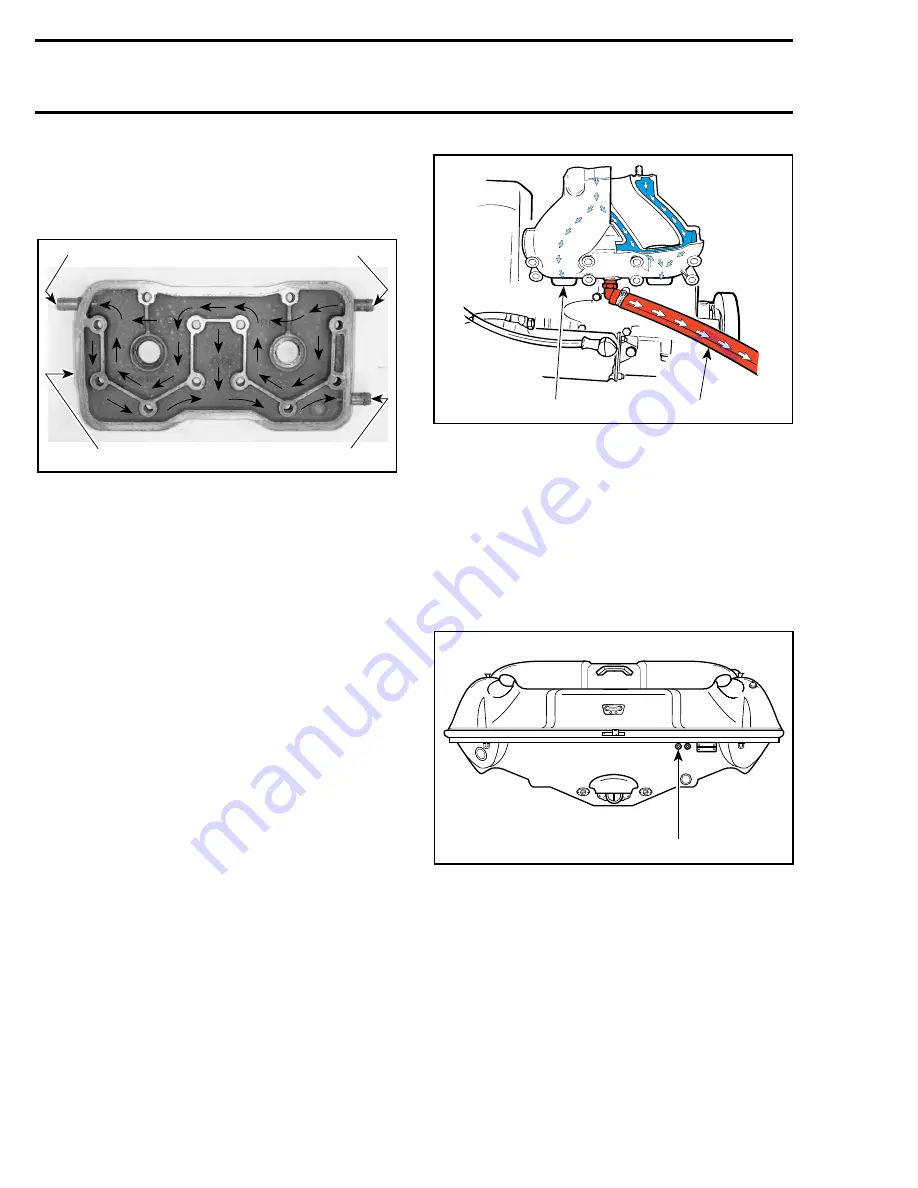

Fresh water from the jet pump enters the head

assembly, cooling the combustion chamber to

prevent detonation.

1. Cylinder head cover

2. Fresh water from jet pump

3. Water exiting head assembly to tuned pipe, exhaust manifold and

cylinders

4. Water from cylinder water jackets exiting engine

On Sportster / Speedster

, water flows out of cylin-

der head toward tuned pipe water jackets. A T-fitting

on the hose allows water to be injected with the

exhaust gases.

On Challenger

, water flows out of cylinder head

toward tuned pipe water jackets. The water to be

injected with the exhaust gases is controlled by

the water flow regulator valve as explained previ-

ously.

All Models

Water injected through the exhaust gases contin-

ues to flow out through the exhaust outlet. Water

in the tuned pipe water jackets continues to flow

through the exhaust manifold water jackets to-

ward the engine cylinder water jackets via pas-

sages below exhaust ports.

TYPICAL - SPORTSTER / SPEEDSTER

1. Water enters cylinder cooling jacket

2. Drain hose

The water continues to the engine cylinder head

and then goes out through the outlet fitting there.

No water enters crankcase.

For a minimum of back pressure in the exhaust,

engine water outlet hose is not connected to the

exhaust. It has its own fitting at the transom (the

same used for flushing the cooling system).

TYPICAL - SPORTSTER / CHALLENGER

1. Engine water outlet

F01E1LA

2

3

1

4

F01E0FA

1

2

F04L2YB

1

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......