Section 08

ELECTRICAL

Sub-Section 02

(MAGNETO SYSTEM)

08-02-3

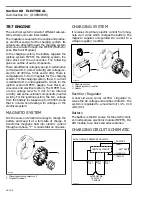

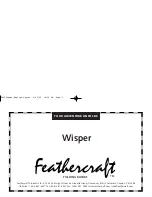

3, Charging System Generator Coil

To replace :

– Heat the armature plate to 93

°

C (200

°

F) around

the screw holes to break the threadlocker

bond.

1. Heat

CAUTION : Protect harness from flame.

– Remove screws.

– Uncrimp and unsolder YELLOW and YELLOW /

BLACK wires from coil.

– Uncrimp and unsolder ground wire (BLACK)

from coil core.

1. Uncrimp and unsolder ground wire (BLACK) here

2. Uncrimp and unsolder YELLOW and YELLOW / BLACK wires

here

– Position new coil, crimp and solder all wires.

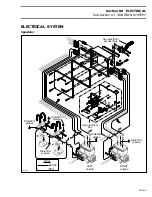

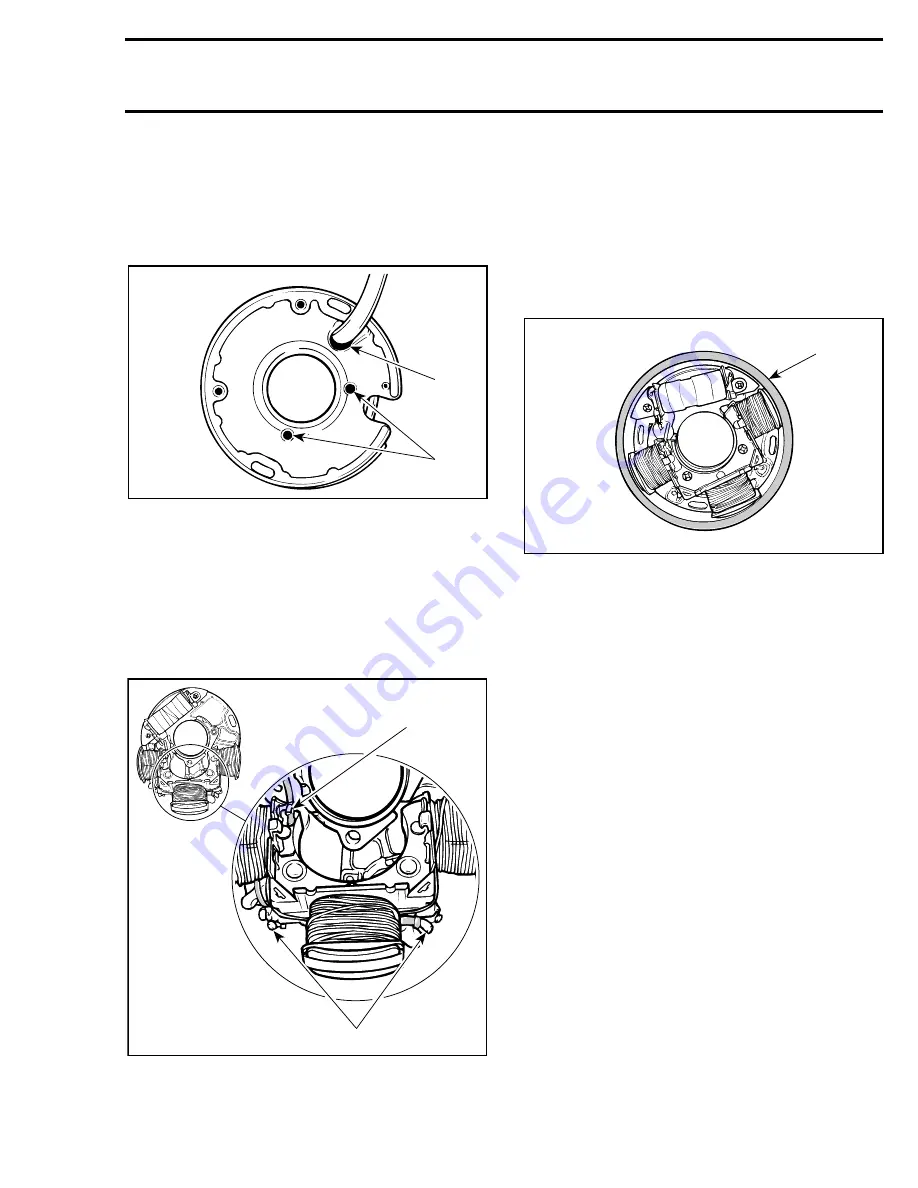

3,4, Charging System Generator Coil

and Screw

Prior to assembly, apply Loctite 242 (blue).

Use magneto coil centering tool (P / N 290 876

922) and install it so that it fits around armature

plate before tightening screws.

1. Magneto coil centering tool (P

/

N 290 876 922)

ASSEMBLY

NOTE :

Always apply dielectric grease on all

electrical connections.

5,6, Screw and Armature Plate

Position the armature plate on the crankcase,

aligning the marks on both parts.

Apply a drop of Loctite 242 (blue) on screw

threads and tighten.

7, Ignition Coil

Connect BLACK / RED

/

GREEN wire to ignition

coil terminal (additional BLACK

/

RED on port en-

gine of Speedster model).

INSTALLATION

Refer to ENGINE section 04-03 then look for

PTO

Flywheel and Magneto

for installation.

Perform ignition timing. Refer to

Ignition Sys-

tem

.

A01C2JA

2

1

-

A25E0SA

1

2

A25E0RD

420 8769 22

'

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

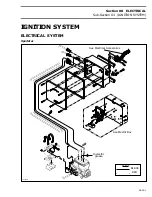

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

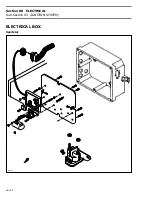

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......