Section 08

ELECTRICAL

Sub-Section 03

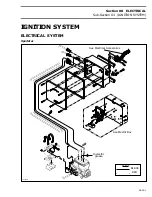

(IGNITION SYSTEM)

08-03-15

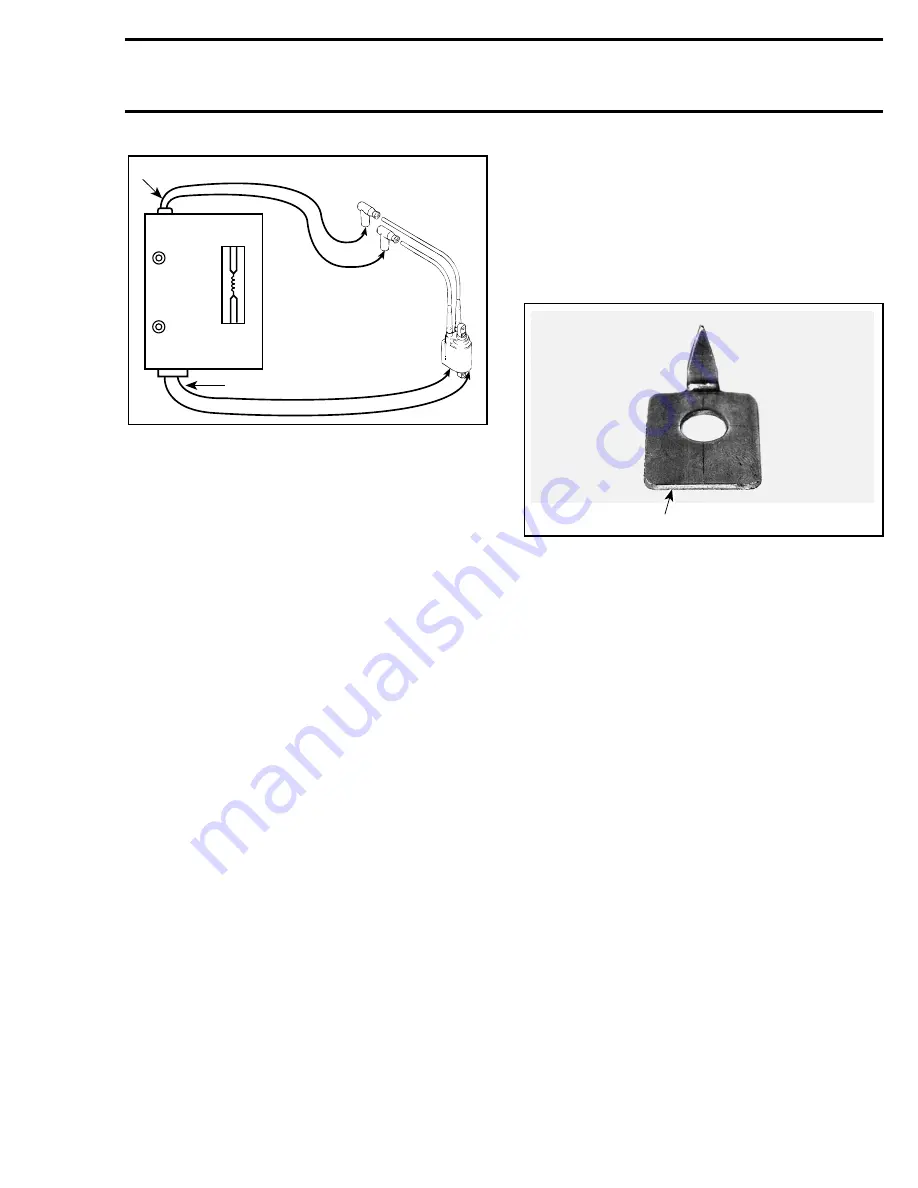

TYPICAL

1. Leads to secondary

2. Leads to primary

4. Turn power switch to 12 volts and you should

observe spark jumping at a predetermined gap

of 7 to 8 mm (.276 to .311 in).

If there is no spark, if it is weak or intermittent, the

coil is defective and should be replaced.

5. Observe tester operating time recommenda-

tions, usually about 5 minutes per coil is suffi-

cient.

IGNITION TIMING, 787 ENGINE

Overview

Normally ignition timing adjustment should not be

required. It has been set at factory and it should

remain correctly adjusted since every part is fixed

and is not adjustable. The only time the ignition

timing might have to be changed would be when

replacing the crankshaft, the magneto flywheel,

the trigger coil, the Nippondenso DC-CDI module

or the MPEM. If the ignition timing is found incor-

rect, you should first check for proper crankshaft

alignment. This might be the indication of a twist-

ed crankshaft.

With this new CDI system, the ignition timing can

be checked with either the engine hot or cold. Be-

sides the

ignition timing is to be checked at

3500 RPM

with the timing light.

Within 3000 and 4000 RPM, the spark advance

does not change. So when checking timing at

3500 RPM, a change in engine speed within

±

500

RPM will not affect the timing mark when

checked with the timing light.

Ignition Timing Procedure

STATIC TEST

1. To install the new timing mark pointer tool, first

remove PTO flywheel guard. Then remove mid-

dle screw securing the engine to the rear cross-

over motor mount. Reinstall screw with timing

mark pointer tool attached.

1. Timing mark pointer tool (P / N 295 000 135)

2. Install a TDC gauge in MAG side spark plug

hole. Rotate PTO flywheel until piston is at top

dead center.

3. From this point, rotate flywheel clockwise

(when facing it) until piston is at 3.38 mm (.133

in) before top dead center.

4. Scribe a mark on PTO flywheel aligned with

timing mark pointer tool.

5. Remove TDC gauge, reinstall spark plug and

connect wire.

DYNAMIC TEST

1. Connect an induction-type tachometer (P / N

295 000 100) to spark plug wire.

2. Check ignition timing using a stroboscopic tim-

ing light connected to the MAG side spark plug

cable. Rev the engine to 3500 RPM and point

beam of timing light straight in line with timing

mark pointer.

CAUTION : If engine is to be run more

than a few seconds, connect a garden

hose and supply water to the engine to proper-

ly cool it.

NOTE :

If mark on PTO flywheel is perfectly

aligned with timing mark pointer, no adjust-

ment is required. If it is not the case, refer to the

following procedure.

ON

OFF

12 V

6 V

F01H55A

1

2

F01H54A

1

-

'

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

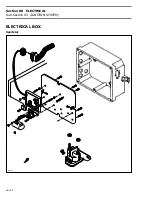

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

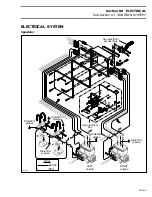

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......