Section 09

PROPULSION AND DRIVE SYSTEMS

Sub-Section 01

(PROPULSION AND DRIVE SYSTEMS)

09-01-16

1. Seal lip

2. Press wear ring

If a press is not readily available, a piece of wood

such as a 2 x 4 x 12 in. long, can be used.

Manually engage ring in housing making sure it is

equally inserted all around. Place wood piece over

ring. Using a hammer, strike on wood to push

ring. Strike one side then rotate wood piece about

90

°

and strike again. Frequently rotate wood

piece so that ring slides equally all around until it

seats into bottom of housing.

1. Piece of wood

2. Seal lip here

3. Wear ring

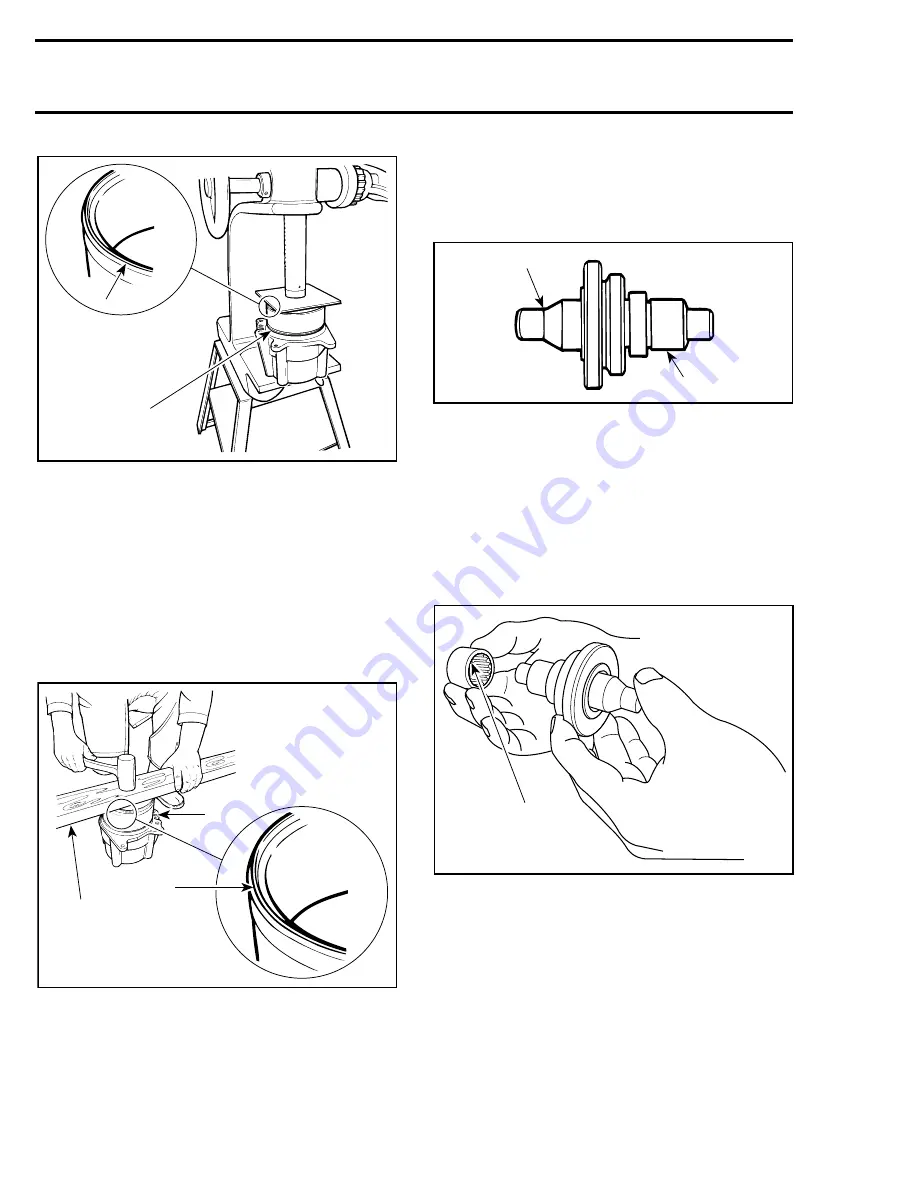

21,22, Seal and Needle Bearing

Bearings and seal will be properly installed in

housing using bearing / seal installer tool (P / N

295 000 107).

BEARING

/

SEAL INSTALLER TOOL

1. Seal end

2. Bearing end

Stamped end of bearings (showing identification

markings) must be located toward outside of

housing.

Properly insert bearing on tool. Using an arbor

press only, push tool until tool flange contacts

housing. Proceed the same way for both bear-

ings.

1. Stamped end this side

CAUTION : Never hammer the bearing

into its housing.

F01J5DA

1

2

F01J5EA

1

3

2

F01J4KA

2

1

F01J1HA

1

-

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......