Section 04

ENGINE

Sub-Section 04

(BOTTOM END)

04-04-9

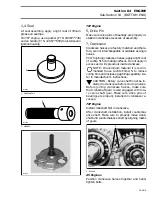

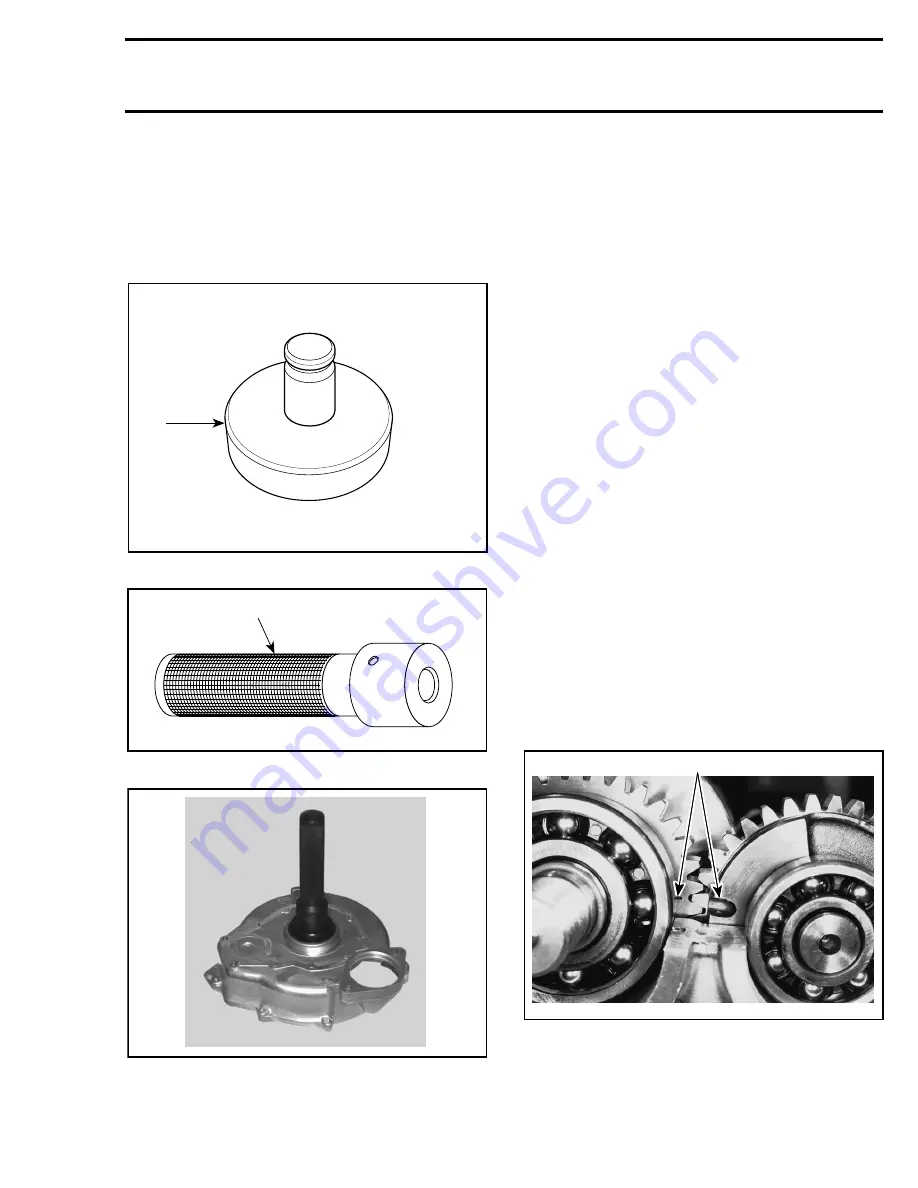

1,4 Seal

At seal assembly, apply a light coat of lithium

grease on seal lips.

On

787 engine

, use a pusher (P / N 290 877 740)

and an handle (P / N 420 877 650) to install seal in

ignition housing.

1. Seal pusher

1. Handle

787 Engine

5, Drive Pin

Make sure drive pins of bearings are properly in-

stalled in crankcase recesses at assembly.

7, Crankcase

Crankcase halves are factory matched and there-

fore, are not interchangeable or available as single

halves.

Prior to joining crankcase halves, apply a light coat

of Loctite 515 on mating surfaces. Do not apply in

excess as it will spread out inside crankcase.

NOTE :

On aluminum material it is recom-

mended to use Loctite Primer N to reduce

curing time and increase gap filling capability. Re-

fer to manufacturer’s instructions.

CAUTION : Rotary valve shaft must be in-

stalled in crankcase before closing halves.

Before joining crankcase halves, make sure

that crankshaft gear is well engaged with rota-

ry valve shaft gear. Make sure drive pins of

bearings are properly installed in crankcase re-

cesses.

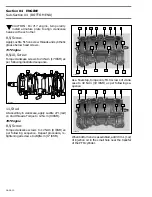

787 Engine

Install crankshaft first in crankcase.

After crankshaft installation, install counterbal-

ance shaft. Make sure to properly index crank-

shaft and counterbalance shaft by aligning marks

of gears.

1. Marks

All Engines

Position crankcase halves together and hand-

tighten bolts.

F04D0BA

1

A00C3VA

1

F04D0CA

'

-

F01D80A

1

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......